MOB

MOB

+86 15888002607

E-MAIL

bob@xinchang-machinery.com

E-MAIL

bob@xinchang-machinery.com

A. Application

The wire rod forming machine can produce wire rods with a diameter of 2.0-12.0mm. The machine adopts a special computer control system for wire rod forming machines and imported high-precision servo motors. The computer has Chinese and English interfaces, easy to operate and accurate positioning. It can store hundreds of processing programs with different specifications, which can shorten the time for the next debugging. According to the working conditions of the screen, the outer diameter and angle of the product can be corrected at any time. The automatic stop design and automatic acceleration function of the bobbin when the wire is disconnected, broken or tangled makes the production easier and more effective. Applicable to production: car seat suspension spring, sun visor frame, car door lock lever, handicraft metal wire, sanitary ware tableware bracket, storage cage, shopping cart and other wire forming equipment.

B. Features

1. There are 7 sets of straightening wheels in the vertical and horizontal directions to ensure the straightness of the wire feeding.

2. There are 3 sets of wire feeding wheels, the accuracy is 280mm±0.1mm

3. Elevating working table is suitable for bending long wires

4. Equipped with a wire tidying mechanism, the wire will not be tangled

C. Advantages

1. The computer can be turned on and off quickly, the operation is simple and convenient, and it supports multi-language operation. The computer interface can change the program while producing and adjusting the speed.

2. The configuration adopts all imported high-precision high-speed servo motors and all imported reducers, and the stable and durable production speed is more than 30% higher than that of similar products in domestic counterparts.

3. The program can realize that there is no change in the angle when the angle is bent at different speeds, and the production stability is better.

4. Imported accessories are used for important parts such as bearings and gears, and the equipment is durable and reliable.

5. High precision, can make wire forming products within the range of 2.0-14 mm wire diameter, and the error is reduced to 0.1 mm

6. Perfect after-sales service system, free technical training support! Equipment maintenance for life!

D. Machine models and specifications

|

Model |

CNC-7-60 |

CNC-7-80 |

CNC-7-120 |

CNC-7-140 |

|

Wire diameter |

2-6mm |

3-8mm |

4-12mm |

5-14mm |

|

Axis numbers |

7 |

7 |

7 |

7 |

|

Wire feeding precision |

±0.01-±9999.99 |

±0.01-±9999.99 |

±0.01-±9999.99 |

±0.01-±9999.99 |

|

Cam precision |

±0.01°-±359.° |

±0.01°-±359.° |

±0.01°-±359.° |

±0.01°-±359.° |

|

Feeding length |

limitless |

limitless |

limitless |

limitless |

|

Speed of feeding |

100m/min |

100m/min |

100m/min |

100m/min |

|

Feeding axis servo motor |

2.7kw |

2.7kw |

4.5kw |

11kw |

|

wire turning axis servo motor |

1.2kw |

1.2kw |

2.7kw |

4.5kw |

|

Bending axis servo motor |

0.75kw |

1.2kw |

2.7kw |

5.5kw |

|

Lifting servo motor |

0.75kw |

0.75kw |

2.7kw |

2.7kw |

|

Twisting & Lifting servo motor |

0.75kw |

0.75kw |

2.7kw |

2.7kw |

|

Turning center axis servo motor |

1.2kw |

1.2kw |

2.7kw |

5.5kw |

|

Cutting axis servo motor |

0.75kw |

0.75kw |

2.7kw |

4.5kw |

|

overall size |

290x190x170cm |

410x200x190cm |

425x200x190cm |

445x200x190 |

|

Machine weight |

2000kg |

2800kg |

3800kw |

4000kg |

E. Main configuration

|

Parts name |

Brands |

|

Servo motor & encoder |

Sanyo |

|

Guide rails & ball screw |

Hiwin |

|

Switching power supply |

Meanwell |

|

Touch screen |

AUO Taiwan |

|

Frequency converter |

Delta |

|

CNC system |

Topcon Japan |

|

Bearings |

NSK |

|

Reduction gears |

Neugart Germany/PHT of Taiwan |

|

Keyboard |

Logitech |

|

Computer |

Topcon Japan |

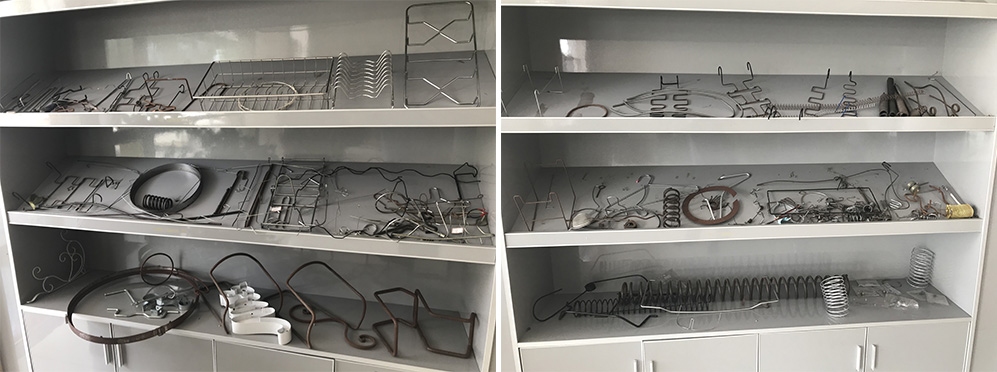

F. Samples photos