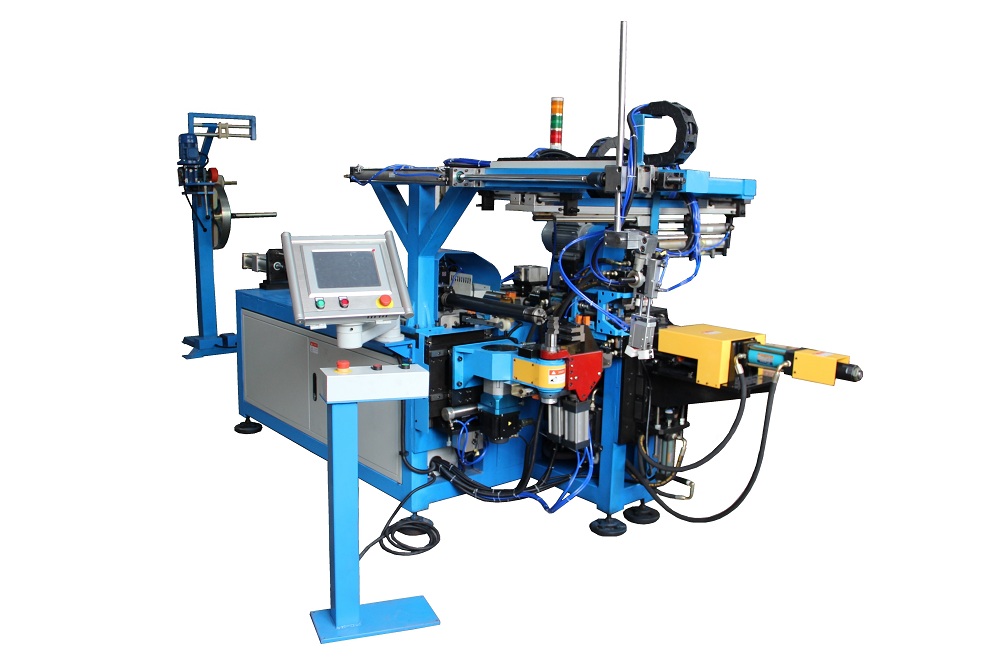

Automatic Decoiling,bending And Pipe End Processing Integrated Machine

(Total 1 Products)-

Min. Order:1Automatic Pipe Decoiling&Bending Machine with End Finishing: an integrated and efficient solution for pipe processingIn the automated production line of pipe processing, the continuous operation from raw material unwinding to forming and bending...

This advanced all-in-one automated system seamlessly integrates three essential tube fabrication processes—decoiling, precision bending, and pipe end processing—into a single, highly efficient continuous production line. Specifically engineered for high-volume manufacturing environments, it transforms raw coiled metal tubing (including steel, aluminum, copper, and various alloys) into finished, ready-to-install components with minimal operator intervention.

The machine begins by automatically straightening and cutting the coiled material to precise lengths, then performs complex 2D or 3D bends with CNC-controlled accuracy and repeatability, and finally carries out comprehensive end-processing operations such as flaring, beveling, threading, piercing, or end-forming. Equipped with state-of-the-art programmable logic controllers (PLC), servo-driven bending arms, automatic tool changers, and real-time laser monitoring systems, it guarantees tight tolerances and consistent output quality.

Ideal for HVAC/R systems, automotive exhaust and fuel lines, furniture frameworks, and hydraulic tubing production, this integrated solution eliminates intermediate handling, significantly reduces labor costs, minimizes material waste, and drastically shortens production cycles. It offers exceptional scalability, flexibility, and reliability for industries demanding the highest levels of precision, durability, and manufacturing efficiency.

The machine begins by automatically straightening and cutting the coiled material to precise lengths, then performs complex 2D or 3D bends with CNC-controlled accuracy and repeatability, and finally carries out comprehensive end-processing operations such as flaring, beveling, threading, piercing, or end-forming. Equipped with state-of-the-art programmable logic controllers (PLC), servo-driven bending arms, automatic tool changers, and real-time laser monitoring systems, it guarantees tight tolerances and consistent output quality.

Ideal for HVAC/R systems, automotive exhaust and fuel lines, furniture frameworks, and hydraulic tubing production, this integrated solution eliminates intermediate handling, significantly reduces labor costs, minimizes material waste, and drastically shortens production cycles. It offers exceptional scalability, flexibility, and reliability for industries demanding the highest levels of precision, durability, and manufacturing efficiency.

Automatic Decoiling, Bending & Pipe End Processing Integrated Machine

Revolutionizing industrial pipe fabrication, this advanced integrated machine seamlessly combines three critical processes—decoiling, bending, and pipe end processing—into a single, automated workflow. Designed for high - volume production, it transforms raw coiled metal into precision - engineered pipes with finished ends, eliminating manual handling and streamlining manufacturing.