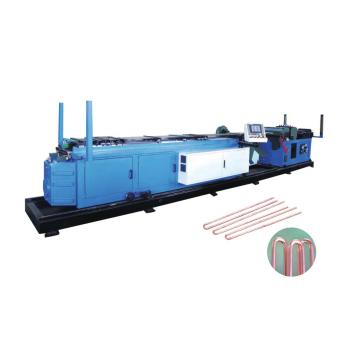

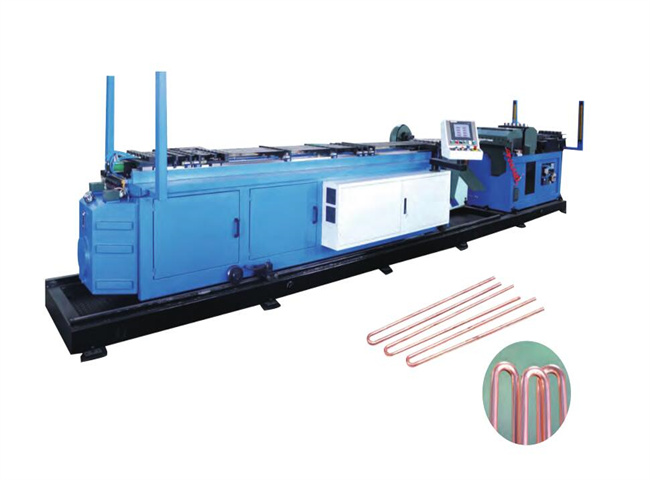

Fully Automatic Hairpin Bender

(Total 1 Products)-

Min. Order:1Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

A Fully Automatic Hairpin Bender is a specialized industrial machine designed to fabricate "hairpin"-shaped copper or aluminum tubes—key components in air conditioners, refrigerators, and HVAC heat exchangers. It automates the entire process from tube feeding to bending, eliminating manual intervention and ensuring consistent, high-precision results.

Working by first cutting metal tubes to preset lengths (typically 300–2000mm), the machine then uses servo-driven bending arms and precision molds to form U-shaped (hairpin) bends with accurate angles (usually 90°–180°) and radii (2–15mm). Advanced models achieve bending tolerances within ±0.1mm, critical for tube-to-fin assembly in heat exchangers.

Key features include high production speed (up to 120 hairpins per minute), automatic tube loading/unloading systems, and CNC controls. Operators can store multiple bending programs, enabling quick switches between tube diameters (6–19mm) and hairpin sizes.

Safety features include emergency stops, protective enclosures, and tube jam detection—preventing damage and ensuring operator safety. Maintenance-friendly designs (e.g., easy access to bending molds) reduce downtime.

Widely used in HVAC, refrigeration, and automotive cooling industries, this machine boosts productivity while maintaining tight tolerances, making it essential for modern heat exchanger manufacturing.

Fully Automatic Hairpin Bender

The fully automatic U-shaped pipe bender is an intelligent device integrating automatic feeding, precise bending and blanking, specially designed for the processing of large quantities of pipe fittings. This equipment adopts a servo drive system to work in coordination with robots, achieving full-process automation from pipe material transportation, positioning to bending forming. It significantly enhances production efficiency and product consistency, making it an ideal choice for upgrading modern factories.