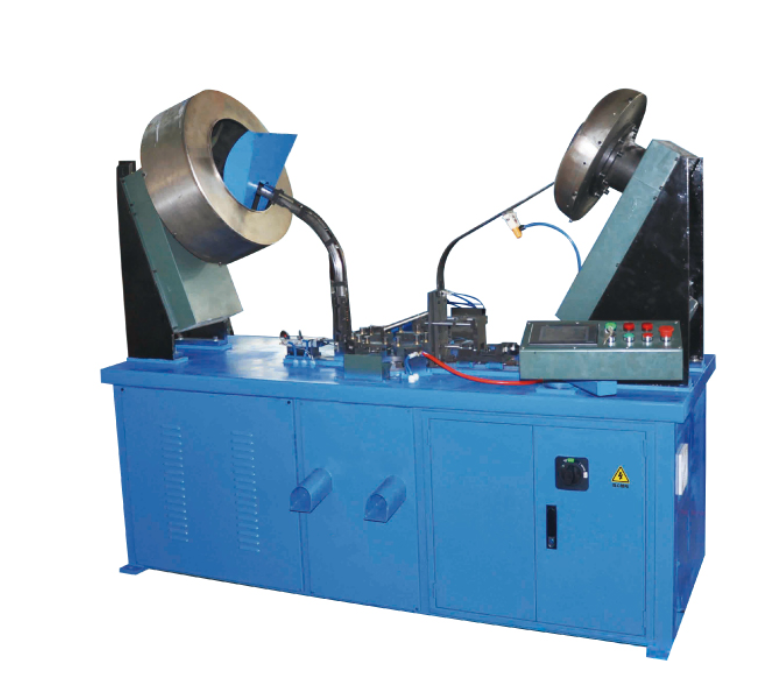

Automatic Ring Inserting Machine

(Total 1 Products)-

Min. Order:1Return Bend Ring Insertion Machine: The precise executor for the assembly of the bend ringIn the manufacturing process of refrigeration equipment and various pipeline systems, the assembly of each component is related to the stability of the overall...

An Automatic Ring Inserting Machine is a specialized automated device designed to insert small circular components—such as O-rings, snap rings, or sealing rings—into workpieces (e.g., mechanical parts, electronic housings, pipes) with high accuracy. It replaces manual insertion, solving issues like low efficiency and inconsistent positioning, and is widely used in automotive, electronics, and plumbing industries.

Core Working Principle

The machine operates through a 4-step automated cycle:

Feeding: A vibratory bowl feeder or conveyor sorts and delivers rings (sizes: 2mm–50mm inner diameter) to the picking zone, ensuring no jams.

Picking: A robotic arm, suction cup, or mechanical gripper (customized for ring material—rubber, metal, or plastic) picks up one ring at a time.

Positioning: Sensors (vision or laser) locate the workpiece’s insertion slot, aligning the ring with millimetric precision (±0.05mm tolerance).

Insertion & Verification: The ring is pressed or snapped into place; a post-insertion sensor checks if it’s correctly seated—rejecting misinserted parts to avoid defects.

Key Advantages

High Efficiency: Processes 300–1,200 rings/hour, 3–5x faster than manual insertion, ideal for mass production.

Consistency: Eliminates human error (e.g., twisted O-rings, misalignment), ensuring 99.9% insertion accuracy—critical for sealing or fastening tasks.

Labor Savings: Reduces reliance on skilled operators; one worker can monitor 2–3 machines, cutting labor costs.

Gentle Handling: Soft grippers or suction cups prevent damage to fragile rings (e.g., rubber O-rings) or delicate workpieces (e.g., plastic electronic casings).

Typical Applications

Automotive: Inserting O-rings into engine gaskets, hydraulic valves, or fuel line connectors to prevent leaks.

Electronics: Fitting snap rings into circuit board brackets or battery compartments for component stability.

Plumbing: Installing sealing rings into pipe joints or faucet valves to ensure water-tight seals.

Medical Devices: Inserting precision rubber rings into syringe components or diagnostic tool housings, adhering to strict hygiene standards.

Operational Tips

Calibration: Adjust feeder speed and gripper force based on ring material (e.g., softer force for rubber, firmer for metal).

Maintenance: Clean the vibratory feeder weekly to remove debris; replace worn grippers monthly to avoid slipping.

Safety: Use safety guards around moving parts and emergency stops to prevent injuries from misfeeds.

In short, the automatic ring inserting machine elevates assembly line reliability and speed, making it essential for industries where precision and efficiency in small-component insertion are non-negotiable.

Automatic Ring Inserting Machine

The fully automatic liner ring assembly machine is an intelligent device specially designed for the pipeline, valve and pressure vessel industries, used for precisely embedding metal or composite material liner rings such as sealing rings and support rings. This equipment adopts high-precision servo positioning and flexible clamping systems to achieve automatic feeding, centering and press-fitting, as well as depth detection of the liner rings, ensuring that the assembly process is zero-damage and fully meets the sealing requirements.