Coil Bender

(Total 1 Products)-

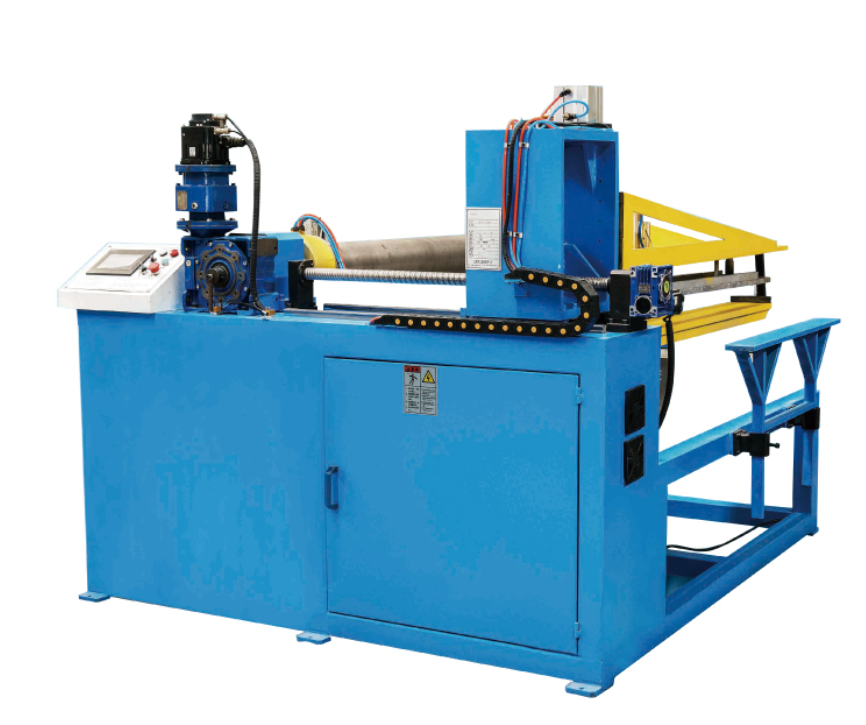

Min. Order:1Coil Bending Machine: a precision master for forming Condenser coilsIn the core process of condenser manufacturing, each step of the forming process directly affects the heat dissipation efficiency and operational stability of the equipment. The...

A Coil Bender is a specialized machine designed to bend metal, plastic, or composite pipes/tubes into continuous coiled shapes (e.g., spiral, helical, or circular coils) with uniform diameter and pitch. Unlike standard benders that create single-angle bends, it focuses on multi-turn coiling—critical for applications requiring compact, space-saving pipe layouts. It is widely used in HVAC, refrigeration, automotive, and renewable energy industries.

Core Working Principle & Key Types

The machine operates through a 4-step automated/semi-automated process, with variations based on

power and coiling method:

Feeding: Pipes/tubes (diameter: 3mm–50mm, length: 1m–20m) are fed into the machine via a motorized roller system, ensuring steady, consistent material flow.

Guiding: A adjustable guide rail aligns the pipe with the coiling mechanism, preventing lateral shifting during bending.

Coiling Execution: The core mechanism shapes the pipe into coils, with two common types:

Mandrel Coil Benders: Use a fixed mandrel (metal rod) as a guide— the pipe is wrapped around it to form coils (ideal for rigid metals like steel, ensuring no pipe collapse).

Mandrel-Free Coil Benders: Rely on precise roller pressure to curve flexible pipes (e.g., aluminum, plastic) into coils, suitable for thin-walled materials to avoid mandrel-induced scratches.

Cutting & Finishing (Optional): After reaching the required number of coils (programmable via a digital panel), a built-in cutter trims the pipe; some models add deburring to smooth coil ends.

Key Advantages

Coil Uniformity: Ensures consistent coil diameter (±0.5mm tolerance) and pitch (distance between coils), critical for heat exchange efficiency (e.g., HVAC coils) or fluid flow stability.

Space Efficiency: Converts straight pipes into compact coils, reducing storage/installation space by 60–80% (e.g., coiled refrigeration tubes in small appliances).

Material Compatibility: Handles diverse materials—from rigid steel (for industrial coils) to flexible copper (for automotive coolant lines) and plastic (for water supply coils).

Efficiency: Processes 5–15 coils/hour (depending on size), 4–7x faster than manual coiling, ideal for batch production (e.g., 100+ coiled tubes for HVAC units).

Programmability: Digital control panels let users set coil diameter (10mm–1m), number of turns (1–100), and feeding speed, enabling quick job switching.

Typical Applications

HVAC & Refrigeration: Bending copper/aluminum tubes into heat exchanger coils (e.g., AC evaporator coils), maximizing surface area for heat transfer.

Automotive: Creating coiled steel tubes for engine oil coolers or fuel lines, fitting into tight under-hood spaces while ensuring fluid circulation.

Renewable Energy: Coiling stainless steel pipes for solar water heater heat collectors, optimizing sunlight absorption via compact coil layouts.

Industrial Manufacturing: Forming plastic coils for chemical transport (resistant to corrosion) or steel coils for compressed air systems, ensuring high-pressure resistance (up to 8,000 psi).

Operational & Maintenance Tips

Mandrel Care (for Mandrel Models): Clean the mandrel after use to remove metal shavings; replace worn mandrels to avoid uneven coils.

Pressure Adjustment: Match roller pressure to material—too much pressure deforms thin pipes; too little causes loose coils.

Maintenance: Lubricate feeding rollers weekly; check cutter sharpness daily (dull cutters cause pipe burrs); calibrate coil diameter settings monthly for precision.

In summary, the coil bender transforms straight pipes into functional, space-saving coils, ensuring performance and efficiency in industries where coiled pipe systems are essential—making it a key tool for modern manufacturing and infrastructure projects.

Coil Bender

The coil bending machine is a professional device specially designed for the refrigeration, automotive and HVAC industries, used for precise bending processing of metal tubes such as copper tubes and aluminum tubes. This equipment adopts servo drive or hydraulic control systems, supporting two-dimensional/three-dimensional multi-angle bending. Combined with intelligent CNC programming, it can quickly achieve complex coil shapes (such as spiral, serpentine, etc.), ensuring consistent bending radii and no wrinkles or deformations.