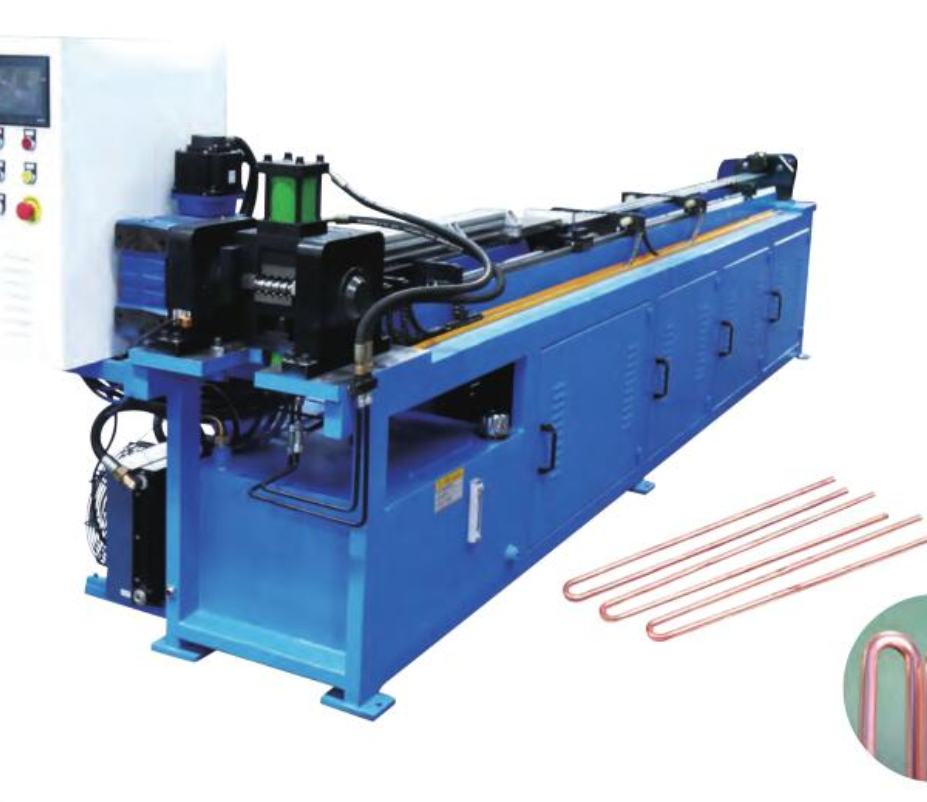

Semi-automatic Hairpin Bender

(Total 1 Products)-

Min. Order:1Semi-Automatic Hairpin Bender-Precision Tube Bending Machine: A flexible choice for precise tube bendingIn the industrial chain of pipe processing and manufacturing, various types of equipment work in concert to jointly ensure the quality and...

A Semi-automatic Hairpin Bender is a specialized piece of equipment designed to shape metal wires (typically copper, aluminum, or steel) into hairpin-like or U-shaped configurations, widely used in industries such as electrical engineering (for motor stators/rotors), automotive (for wiring harnesses), and jewelry making.

Core Functionality

Unlike fully manual benders that rely entirely on human force and skill, it combines manual operation (e.g., wire feeding, material loading) with automated bending mechanisms. Users position the wire into the machine’s guide slot, and the built-in motor or pneumatic system executes precise, repeatable bends at preset angles (usually 90°, 180°, or custom degrees) with minimal human error. Most models feature adjustable bending dies to accommodate different wire diameters (common range: 0.5mm–5mm) and hairpin lengths, enhancing versatility.

Key Advantages

Precision & Consistency: Automated bending ensures uniform dimensions across batches, critical for parts requiring tight tolerances (e.g., electrical components).

Efficiency Boost: Cuts down manual labor time by 30–50% compared to hand benders, ideal for small-to-medium production runs (100–10,000 units/day).

Ease of Use: Intuitive control panels (with digital displays for parameter setting) reduce training time; operators need basic technical skills, not expert craftsmanship.

Cost-Effectiveness: Lower upfront cost than fully automatic lines, making it accessible for small businesses or workshops with variable production needs.

Typical Applications

Electrical Industry: Producing hairpin windings for high-efficiency motors (e.g., EV motors, industrial pumps) to improve heat dissipation and conductivity.

Automotive Sector: Fabricating U-shaped wire clips for securing hoses, cables, or interior components.

Craft & Jewelry: Creating custom hairpins, decorative U-pins, or findings for accessories.

Hardware Manufacturing: Making small fasteners, brackets, or support pins for appliances.

Operational Tips

To maintain performance, regular maintenance is key: clean bending dies to prevent metal shavings buildup, lubricate moving parts monthly, and calibrate angle settings periodically. Operators should wear safety gloves and goggles to avoid wire snags or debris injuries.

In short, the semi-automatic hairpin bender bridges the gap between manual flexibility and automated precision, making it a reliable solution for businesses seeking to balance quality, speed, and cost in wire forming tasks.

Semi-Automatic Hairpin Bender

The semi-automatic U-shaped pipe bender is a pipe processing equipment specially designed for the refrigeration, automotive and HVAC industries. It is suitable for U-shaped bending and forming of metal pipes such as copper pipes and aluminum pipes. This equipment integrates the advantages of manual feeding and mechanical pipe bending. It achieves precise pipe bending Angle control through hydraulic or servo drive systems. It is easy to operate and has low maintenance costs, making it an ideal choice for medium and small batch production or diversified product processing.