-

Stud welding is a highly efficient method for joining metal components, utilizing an arc to melt the surfaces of a metal stud and a workpiece, followed by the application of pressure to form a strong bond. Since its invention in 1918, stud welding has gained widespread recognition for its speed, reliability, and cost-effectiveness, particularly with advancements made after World War II. There are two primary types of

-

Certainly! Here’s the content in English: Site stud welding is being transformed by advancements in battery technology, making the process more efficient and accessible on construction sites, particularly when paired with diesel generators. Traditionally reliant on bulky equipment and stable power supplies, stud welding faced challenges such as power constraints, cumbersome setups, limited mobility, and frequent downtime. However, new battery-powered systems provide a stable power source, a

-

Stud welding is a highly efficient and cost-effective technique for joining circular fasteners, or studs, to flat surfaces, utilizing a welding arc and pressure. This one-step fastening system employs weld studs available in various styles, sizes, and shapes, making it suitable for a wide range of applications. The essential equipment includes a direct current power supply, a controller, a weld gun, and connecting cables. Arc stud welding is particularly effective for attaching large diameter

-

Knowing when to replace your stud welding equipment is vital for maximizing your return on investment. Many manufacturing industries continue to rely on outdated welding machines for years, often unaware that these tools can significantly inflate manufacturing costs. Key signs that indicate it's time for an upgrade include high repair costs, low productivity, increased safety risks, lack of spare parts, and poor portability. If your welding machine frequently breaks down, incurs high maintena

Coils Bending Machine

- manufacturer, factory, supplier from China(Total 12 Products for Coils Bending Machine)

-

Supply Ability:100 Set/ YearOverview Product Description Detailed Photos Company Profile FAQ

-

Automatic Serpentine Fin Bender for HVAC Evaporators: An efficient shaping tool for HVAC evaporatorsIn HVAC systems, the performance of the evaporator is directly related to the overall cooling and heating efficiency. As the core structure of the...

-

Automatic Fin Insertion & Tube Expansion Machine for HVAC: An efficient assembly engine for HVAC equipment In HVAC equipment production, the Automatic Fin Insertion & Tube Expansion Machine is pivotal for evaporators and condensers. It...

-

CNC Fin Evaporator Bending Machine: the core equipment for precision machining of evaporatorsIn the production of the core component of refrigeration equipment - the finned Evaporator, the CNC Fin Evaporator Bending Machine, with its precise...

-

Supply Ability:30sets/YearOverview Product Description Technical Parameters Finished product display Company Profile FAQ

-

Supply Ability:100 Set/ YearOverview Product Description Detailed Photos Company Profile FAQ

-

Supply Ability:500 Set/YearOverview Product Description Detailed Photos Company Profile FAQ

-

Brand:XinchangPlace of Origin:Ningbo,ChinaCNC 2D & 3D Wire Bending Machine: The creative embodiment of metal wire formingIn the field of metal wire processing, the precise forming of complex shapes is the key to product design and functional realization. The CNC 2D & 3D Wire Bending...

-

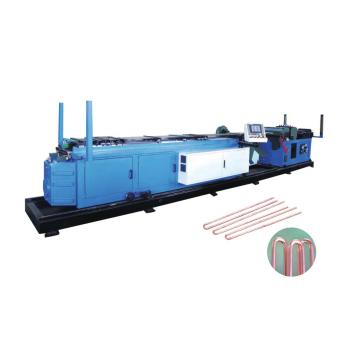

Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

-

Semi-Automatic Hairpin Bender-Precision Tube Bending Machine: A flexible choice for precise tube bendingIn the industrial chain of pipe processing and manufacturing, various types of equipment work in concert to jointly ensure the quality and...

-

Automatic Hairpin Bender for Refrigeration Tubes: Automation pioneer for processing refrigeration tubesIn the precise chain of refrigeration equipment manufacturing, each piece of equipment plays a key role in its respective link. The Friction...

-

Coil Bending Machine: a precision master for forming Condenser coilsIn the core process of condenser manufacturing, each step of the forming process directly affects the heat dissipation efficiency and operational stability of the equipment. The...

Related Information