-

Friction welding is a solid-state bonding process that joins materials through the heat generated by friction while one workpiece rotates against another under compressive force. Established by KUKA in 1966, this technology enables the creation of high-integrity, full-contact joints without the need for filler materials, flux, or shielding gases. The process consists of several phases: frictional contact, where one piece rotates and pressure is applied; the friction phase, where heat is gener

-

Friction welding has emerged as a highly effective joining technique across various industries, celebrated for its ability to produce high-strength joints, reduce material waste, and maintain environmental sustainability. This document offers an in-depth review of recent advancements in friction welding processes, including rotary friction welding, linear friction welding, and friction stir welding. It delves into the fundamental principles, process parameters, microstructural evolution, and

-

Friction welding offers a cost-effective solution for the food industry, especially amidst rising raw material prices. This innovative welding method enables the use of lower-cost materials in up to 60% of components without sacrificing performance, ensuring essential criteria such as abrasion resistance, mechanical strength, and compliance with FDA sanitary requirements are met. The process involves rubbing two components together to create friction and heat, forging them into a robust bond

-

Friction welding is a cutting-edge joining technique that revolutionizes the way materials are bonded by utilizing the heat generated through friction rather than relying on external heat sources, resulting in a cleaner and more precise process. This method boasts numerous advantages, including rapid joining capabilities that allow welds to be completed in mere seconds, significantly reducing cycle times. It excels in joining dissimilar metals, broadening design possibilities, while its self-

Low Heat Distortion Projection Welding Machine

- manufacturer, factory, supplier from China(Total 12 Products for Low Heat Distortion Projection Welding Machine)

-

Automatic Projection Welder System for Metal Fabrication: The benchmark of automated projection welding in metal processingIn the field of metal fabrication, from the welding of precision parts to large structural components, efficiency and accuracy...

-

Among the large family of welding equipment, various models each perform their own duties, jointly building a solid connection for industrial production. From the Friction Welding Machine that generates heat through friction to achieve welding, to...

-

Radiator Fin Flash Butt Welding Machine: The efficient core for welding radiator finsIn the production and manufacturing of heat sinks, the welding quality of the heat sinks directly affects the heat dissipation efficiency and the service life of...

-

Condenser & Evaporator Welding Machine for HVAC Systems: Welding assurance for HVAC coreIn HVAC systems, condensers and evaporators, as the core components for heat exchange, their welding quality directly determines the system's cooling...

-

Among the large family of Welding equipment, each type of Machine performs its own duties. The Plate Heat Exchanger Welding Machine, with its precise control over the welding of plate heat exchangers, has become a leader in the industry. Unlike the...

-

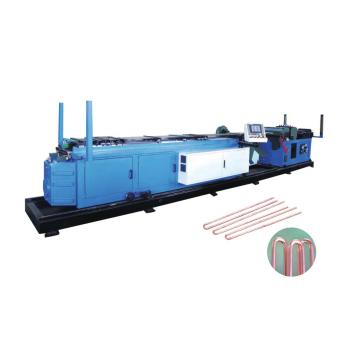

Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

-

Automatic clutch plate projection welding machine: A powerful welding tool for clutch manufacturing In the automotive transmission system, the Welding quality of the Clutch Plate is directly related to the stability of power transmission and driving...

-

Automatic valve core projection welding machine: Precise guarantee for valve core welding In the Valve system of automotive engines, the valve Core, as a key component controlling the intake and exhaust of gases, its Welding quality directly affects...

-

Automatic nut projection welding machine: The efficient and precise choice for nut welding In manufacturing fields such as automobiles and machinery, the connection strength and stability between nuts and workpieces are of vital importance. The...

-

Automatic Brake Shoe Projection Welding Machine: Drive the automation upgrade of brake pad weldingIn the modern production of automotive Brake system components, the Automatic Brake Shoe Projection Welding Machine, with its highly automated...

-

Among the family of Welding equipment, each type of model has its own strengths. The Ring Projection Welding Machine, with its unique design and performance, stands out as a leader in welding ring-shaped workpieces. Unlike the Friction Welding...

-

In the production and processing of spars, the accuracy and firmness of the Welding process directly affect the performance of the spars. The Bobbin Projection Welding Machine, with its outstanding performance designed for SPAR projection welding,...

Related Information