-

Friction welding is a solid-state bonding process that joins materials through the heat generated by friction while one workpiece rotates against another under compressive force. Established by KUKA in 1966, this technology enables the creation of high-integrity, full-contact joints without the need for filler materials, flux, or shielding gases. The process consists of several phases: frictional contact, where one piece rotates and pressure is applied; the friction phase, where heat is gener

-

Friction welding has emerged as a highly effective joining technique across various industries, celebrated for its ability to produce high-strength joints, reduce material waste, and maintain environmental sustainability. This document offers an in-depth review of recent advancements in friction welding processes, including rotary friction welding, linear friction welding, and friction stir welding. It delves into the fundamental principles, process parameters, microstructural evolution, and

-

Friction welding offers a cost-effective solution for the food industry, especially amidst rising raw material prices. This innovative welding method enables the use of lower-cost materials in up to 60% of components without sacrificing performance, ensuring essential criteria such as abrasion resistance, mechanical strength, and compliance with FDA sanitary requirements are met. The process involves rubbing two components together to create friction and heat, forging them into a robust bond

-

Friction welding is a cutting-edge joining technique that revolutionizes the way materials are bonded by utilizing the heat generated through friction rather than relying on external heat sources, resulting in a cleaner and more precise process. This method boasts numerous advantages, including rapid joining capabilities that allow welds to be completed in mere seconds, significantly reducing cycle times. It excels in joining dissimilar metals, broadening design possibilities, while its self-

Rotary Return Bend Blasting Machine

- manufacturer, factory, supplier from China(Total 12 Products for Rotary Return Bend Blasting Machine)

-

Double-spindle friction welding machine for cable joints: Strengthening the welding defense line for power transmissionIn power transmission systems, cable joints are key nodes that ensure the stable transmission of current, and the quality of their...

-

High-Speed Drum Seam Welding Machine: Expert in high-speed sealing for drum weldingIn the field of Drum manufacturing in industries such as chemical engineering, food, and packaging, the sealing performance and Welding efficiency of drums directly...

-

Supply Ability:500 Sets/ YearOverview Product Description Product Parameters Detailed Photos Company Profile FAQ Overview Basic Info. Control Semi-Automatic Frequency Range Intermediate Frequency Electric Current AC Type Butt Welders

-

Brand:XIN CHANGPlace of Origin:NINGBO,CHINAFriction Welding Machine for Drill Rod, Automatic Friction Welding Machine, and Friction Welding Machine for Drill Pipes are advanced industrial solutions designed to enhance the efficiency and durability of metal joining processes. These machines...

-

Return Bend Ring Insertion Machine: The precise executor for the assembly of the bend ringIn the manufacturing process of refrigeration equipment and various pipeline systems, the assembly of each component is related to the stability of the overall...

-

Tube Deburring & Cleaning Machine: The key guardian of welding qualityIn the precise world of metal processing, the perfect presentation of each welding procedure cannot be achieved without meticulous pre-treatment. The Tube Deburring &...

-

Brand:XinchangPlace of Origin:Ningbo,ChinaCNC 2D & 3D Wire Bending Machine: The creative embodiment of metal wire formingIn the field of metal wire processing, the precise forming of complex shapes is the key to product design and functional realization. The CNC 2D & 3D Wire Bending...

-

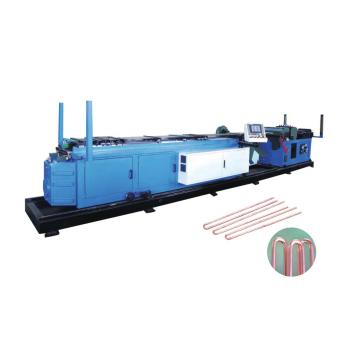

Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

-

Semi-Automatic Hairpin Bender-Precision Tube Bending Machine: A flexible choice for precise tube bendingIn the industrial chain of pipe processing and manufacturing, various types of equipment work in concert to jointly ensure the quality and...

-

Automatic Hairpin Bender for Refrigeration Tubes: Automation pioneer for processing refrigeration tubesIn the precise chain of refrigeration equipment manufacturing, each piece of equipment plays a key role in its respective link. The Friction...

-

Coil Bending Machine: a precision master for forming Condenser coilsIn the core process of condenser manufacturing, each step of the forming process directly affects the heat dissipation efficiency and operational stability of the equipment. The...

-

Portable AC Coil Expander and Bender Machine: A flexible tool for processing air conditioning coilsIn the air conditioning manufacturing industry, the processing quality of coils directly affects the cooling efficiency and operational stability of...

Video

Related Information