Equipment For In-line Type Evaporator

(Total 6 Products)-

Min. Order:1Heavy-Duty Long U-Bend Tube Bending Machine: A hardcore tool for processing long U-shaped bent tubesIn fields such as large industrial pipelines and heat exchange equipment, the processing accuracy and structural strength of Long U-shaped bent tubes...

-

Min. Order:1Aluminum Fin Tube Expander for Evaporator Coils: a key tool for efficient processing of Evaporator coilDuring the processing of the core component of refrigeration equipment - the evaporator coil, the tight combination of aluminum fins and tubes...

-

Min. Order:1Hydraulic Push-Type Tube Expander: An efficient helper for precise connectionsIn the precise world of industrial manufacturing, the stable connection of pipes and pipe fittings is the core link to ensure the efficient operation of equipment, and...

-

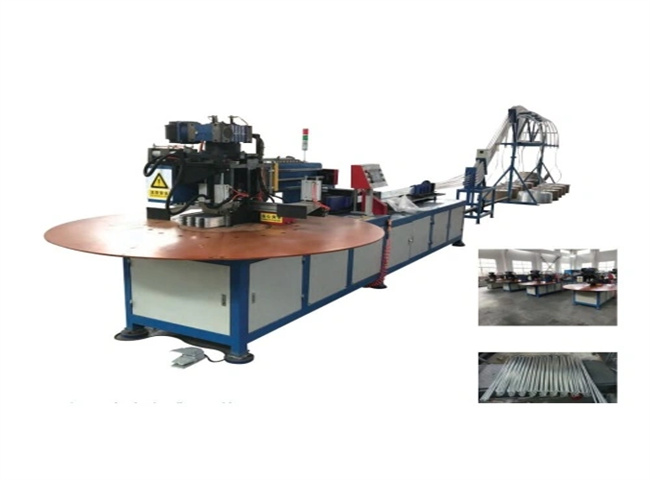

Min. Order:1Automatic Multi-Head Tube Bending Machine: High-efficiency equipment for precise bending of multiple tubesIn industries such as air conditioning and automotive refrigeration that require complex pipeline systems, the synchronous Bending forming of...

-

Min. Order:1Copper-Aluminum Pipe Butt Welding Machine: An innovative solution for connecting copper-aluminum pipesIn the pipeline systems of industries such as refrigeration and HVAC, the connection of dissimilar materials like Copper and Aluminum has always...

-

Min. Order:1Fin Press Machine for In-Line Type Evaporators: Key equipment for fin forming of in-line type evaporatorsIn the production of in-line Evaporators, the forming quality of fins directly affects the heat exchange efficiency and structural stability of...

Equipment For In-line Type Evaporator refers to specialized manufacturing systems designed for continuous production of evaporator cores used in refrigeration and air-conditioning systems. These integrated production lines automate the entire manufacturing process, ensuring high precision and efficiency in creating heat exchange components critical for cooling equipment performance.

Working Principle

The in-line production process starts with material feeding, where aluminum or copper tubes and fins are supplied continuously. Automated machinery then assembles fins onto tubes through expansion or bonding, followed by bending, cutting, and forming operations to shape the evaporator core. Welding or brazing stations join components securely, while leak detection systems inspect for faults. The continuous flow ensures each production stage connects seamlessly, minimizing downtime between processes.

Structure and Components

Key components include automatic feeding systems, fin punching machines, tube expanding equipment, bending robots, welding/brazing stations, leak testers, and conveyor systems. Feeding systems ensure steady material supply, while fin punches create precise fin patterns. Tube expanders enhance fin-tube contact for better heat transfer. Bending robots shape cores into required configurations, and welding stations form airtight joints. Leak testers use pressure or vacuum methods to detect defects, with conveyors moving products through each stage.

Advantages

Continuous in-line production significantly increases output compared to batch processes, boosting efficiency by 30-50%. Automated operations ensure consistent component quality and dimensional accuracy, reducing performance variations in final evaporators. Integrated quality checks minimize defective products, lowering material waste. Labor costs are reduced through automation, while standardized processes simplify maintenance and training requirements.

Applications

These systems are essential in manufacturing evaporators for household refrigerators, air conditioners, and commercial cooling units. They produce evaporator cores for automotive air conditioning systems and industrial refrigeration equipment. Specialized versions cater to low-temperature evaporators for freezers and cryogenic applications, as well as compact evaporators for medical refrigeration devices.

Development Trend

Modern in-line evaporator equipment integrates IoT and data analytics for real-time production monitoring. AI-powered vision systems enhance quality inspection accuracy. Energy-efficient motors and heat recovery systems reduce environmental impact. Flexible designs allow quick reconfiguration for different evaporator sizes and types. Predictive maintenance features minimize downtime, while improved human-machine interfaces simplify operation and troubleshooting, aligning with smart manufacturing trends.

Equipment for In-line Type Evaporator

The dedicated production equipment for online evaporators is an automated system designed for efficient continuous production. It integrates functions such as precision forming, welding, assembly and inspection, and is suitable for the manufacturing of evaporators in the refrigeration, chemical and food processing industries.This equipment adopts high-precision mold positioning and automated welding technology (such as laser welding or high-frequency brazing) to ensure the airtightness and heat exchange efficiency of the evaporator pipeline.