Lattice girders, key for construction (tunnel support, bridge reinforcement), rely on resistance welding machines as core equipment in their production lines. These machines use the "resistance heat + pressure bonding" principle to join steel bars/wires into lattice structures, ensuring the girders’ load-bearing capacity and structural stability.

Core Applications in Production Lines

Main Bar & Diagonal Bar Welding: Lattice girders have parallel main bars (6-16mm diameter) and crossed diagonal bars. Spot resistance welders target intersections, delivering 25-45kA current and 500-1200N pressure. They form strong joints (shear strength ≥450MPa) in 30-80ms, critical for withstanding tunnel/bridge loads.

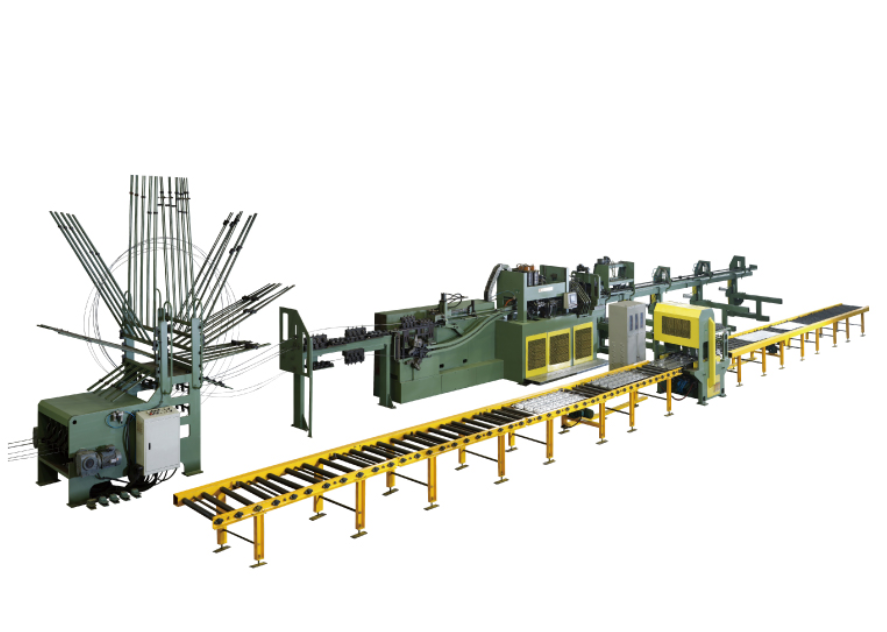

Continuous Production Integration: Automated lines pair resistance welders with feeding/conveying systems. Welders work at 2-5 joints per second, enabling 100-200m of lattice girder production hourly. This meets large-scale construction needs, e.g., tunnel projects requiring 1000+m daily.

Customized Girder Adaptation: For girders of varying lengths (2-12m) or bar spacings (100-300mm), welders adjust parameters via PLC systems. They switch between single-point/multi-point welding modes, ensuring consistency even for non-standard designs.

Key Advantages for Production Lines

High Efficiency: Far faster than manual welding, cutting production time by 60%. Automated lines with these machines avoid delays from manual errors.

Uniform Quality: Precise control of current, time, pressure reduces defect rates below 0.3%. Welded joints resist corrosion and fatigue, meeting construction standards (e.g., ISO 17660).

Cost Savings: No consumables (welding wire/gas) are needed. Low maintenance (parts last 10-18 months) lowers long-term costs for manufacturers.

Safety: Enclosed welding chambers prevent sparks/smoke, complying with workplace safety rules, which is vital for long-running production lines.

Future Trends

Smart Monitoring: Sensors will detect bar diameter/material, auto-adjusting parameters to avoid weak joints, with data logged for quality tracing.

Energy Efficiency: Inverter tech will cut energy use by 30% vs. traditional machines, aligning with green construction goals.

Flexible Expansion: Modular welders will integrate with 3D scanning, enabling quick reconfiguration for complex lattice girder designs, supporting diverse construction projects.

Resistance welding machines are indispensable for lattice girder production lines, driving efficiency, quality, and adaptability to meet the growing demands of modern construction.