Lattice beams, as important load-bearing structures in fields such as construction and Bridges, their Welding quality and Production efficiency are related to the safety and progress of the project.

Lattice Girder Welding Production Line, with its integrated welding solution, has become the core force in the mass production of lattice beams.

Facing the complex grid structure of the lattice beam, although the

Friction Welding Machine can achieve the connection of some components, when dealing with the welding requirements of multiple nodes and multiple directions, it is difficult to ensure the consistency of each node, and the stress generated by friction is prone to affect the overall stability of the lattice beam. Lattice Girder Welding Production Line, through systematic process design, can precisely control each welding point of the lattice beam to ensure uniform welding strength at each node and balance the force of the lattice beam when it is load-bearing.

The

Spot Welding Machine has a relatively high efficiency in single-point welding, but the lattice beam requires a large number of welding points for connection. Relying solely on spot welding equipment is difficult to form a continuous production process, and more manual intervention is prone to errors. Lattice Girder Welding Production Line integrates the automated spot welding module, which can complete intensive and precise spot welding operations according to the preset program, significantly improving production efficiency while ensuring the stability of weld point quality.

Unlike the

Butt Welding Machine which focuses on material butt Welding, Lattice Girder Welding Production Line can not only complete the butt welding of components, but also meet the crisscrossing connection requirements in lattice beams. It can adjust the welding parameters according to different specifications of lattice beams to ensure that the welding at the connection points and intersection points achieves the best effect, taking into account both the firmness and integrity of the structure.

Seam Welding machines are mostly used for continuous welding of sealed welds, while the welding of lattice beams pays more attention to the strength of structural nodes. Lattice Girder Welding Production Line abandons the unnecessary sealing process and focuses on the reinforcement welding of nodes. By strengthening the shear resistance of the weld seam, it ensures that the lattice beam will not have node fracture when subjected to load.

The

Laser Welding Machine for Steel Ring is renowned for its high precision, and Lattice Girder Welding Production Line is no less accurate in the welding of lattice beams. The intelligent positioning system it is equipped with can accurately identify each welding node, control the welding error within an extremely small range, ensure the dimensional accuracy of the lattice beam, and meet the strict requirements of engineering installation.

Stud Welding Machine plays an auxiliary role in the connection between studs and Lattice beams, while lattice Girder Welding Production Line undertakes the important task of welding the main structure of lattice beams. The two cooperate with each other to jointly ensure the overall quality of lattice beams. By choosing Lattice Girder Welding Production Line, efficient welding of lattice beams from components to finished products can be achieved, providing high-quality load-bearing structures for large-scale projects.

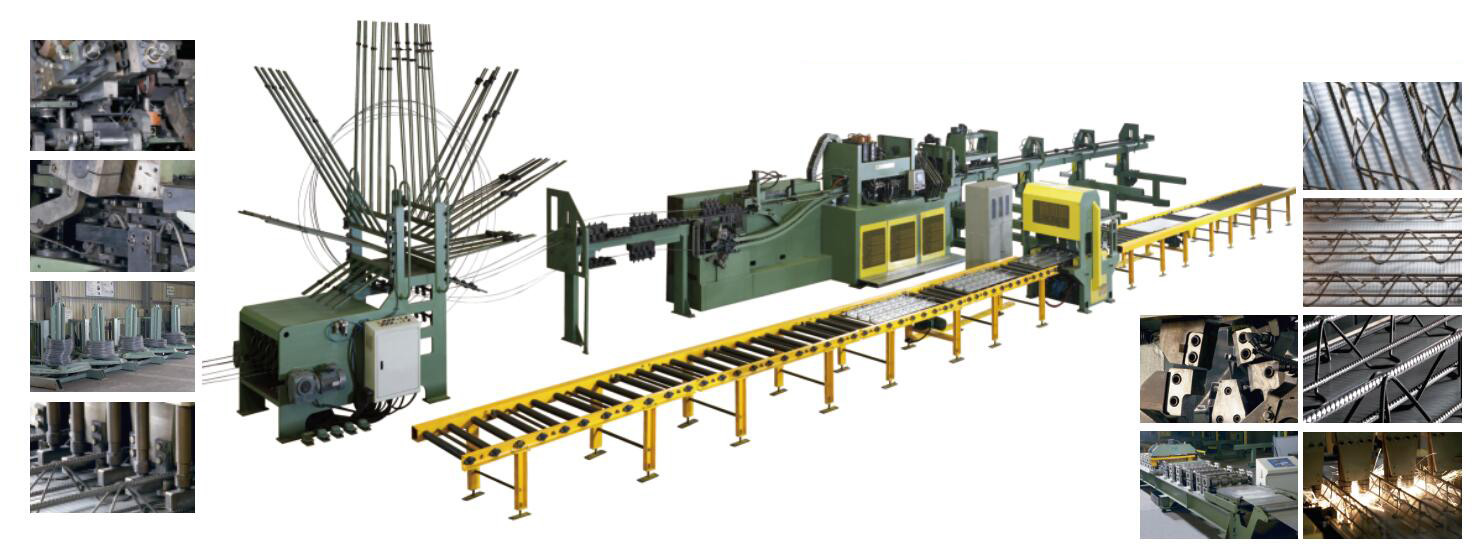

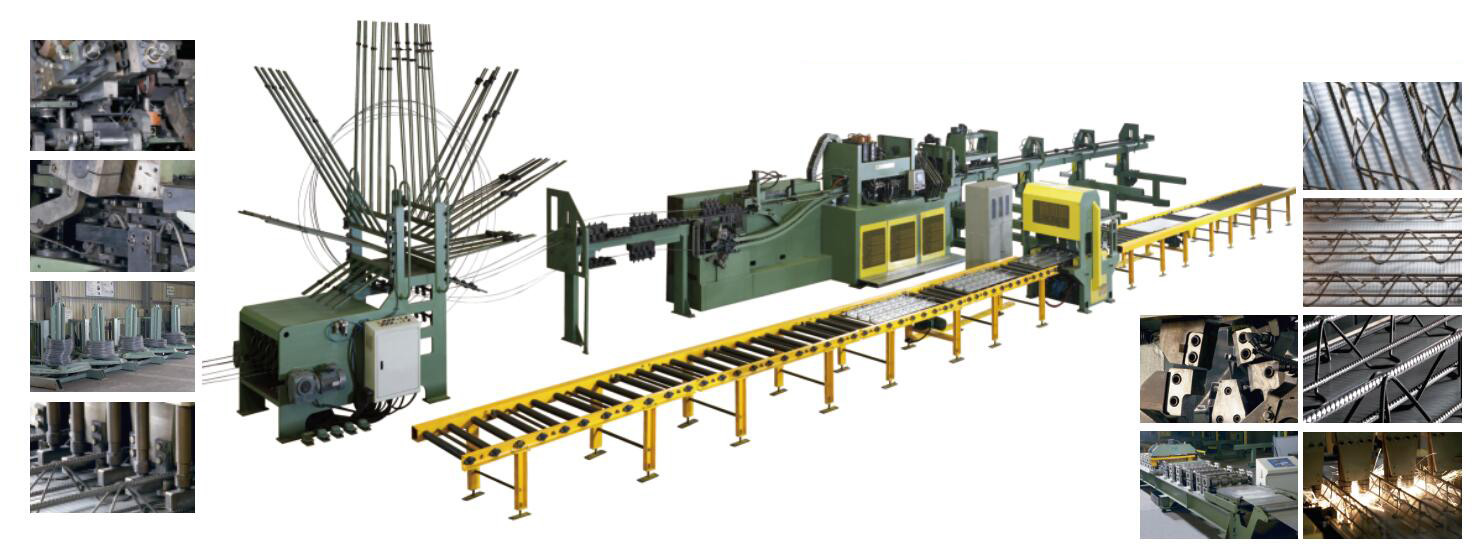

General description

JGH self-supported steel deck whole set production line consists of truss welding line, bottom panel forming machine and steel

deck spot welding machine, combining mechanism, electricity, hydraulic and pneumatic with microcomputer control, it performs

whole set production process of steel moulding board's truss, galvanized steel forming and assembling & welding.The line's annual

single-round production capacity reaches 300,000 square meters.

Features and application

JSelf -supported steel deck panel is a new type steel structural building material developed for steel construction industry in

recent years.It's now widely applied in steel structural floor deck, bridge, railway and many other places.It's featured by light struc�

ture, high strength and factory production.This construction method of pourling concrete onto steel deck can reduce site workload

greatly and also shortens construction period.

Technics flflow

Steel bar feeding→straightening→assistant bar bending→spot welding→feet bending→truss length-set cutting

Galvanized sheet decoiling→forming→panel length-set cutting

Galvanized sheet and truss assemble&feeding→spot welding→lattice girder products output