AC Spot Welding Machine

(Total 5 Products)-

Min. Order:1AC Spot Welding Machine: Stable and efficient, strengthening the defense line of basic spot weldingAmong the myriad welding scenarios in industrial production, the stability and economy of basic spot welding have always been the core demands of...

-

Brand:xinchangMin. Order:1100KVA Custom Spot Welding Machine: The industry benchmark for customized high-power welding solutionsIn the field of industrial welding, in the face of diverse workpiece materials and complex welding requirements, the power output and customization...

-

Brand:xinchangMin. Order:1Horizontal T-Type Spot Welding Machine: Unlock efficient new experiences in horizontal welding scenarios Usage: Be used for T type point welding of wire.Method named for welders:Spot(projection) welders series: DTN-P-1(2)-LDTN: Pneumatic AC mains...

-

Brand:xinchangMin. Order:1Vertical T-Type Spot Welding Machine: Reconstructing a new benchmark for Precision in Vertical Welding scenariosIn the diverse applications of welding equipment, the structural design and scene adaptability directly determine the operation...

-

Min. Order:1CNC Spot Welding Machine: Precise numerical control, initiating a new era of spot welding automationToday, as industrial manufacturing moves towards intelligence, the precision and automation level of welding equipment have become the core...

AC spot welding machines are widely used devices in metal fabrication, leveraging alternating current to create strong, localized welds. They are integral to industries like automotive, electronics, and appliance manufacturing, valued for their efficiency and reliability.

Working Principle: These machines operate by passing alternating current through overlapping metal workpieces clamped between two electrodes. The resistance at the contact points generates intense heat (typically 800–1500°C), melting the metal surfaces. Simultaneous pressure from the electrodes fuses the molten areas, forming a solid weld nugget as the current stops and the metal cools.

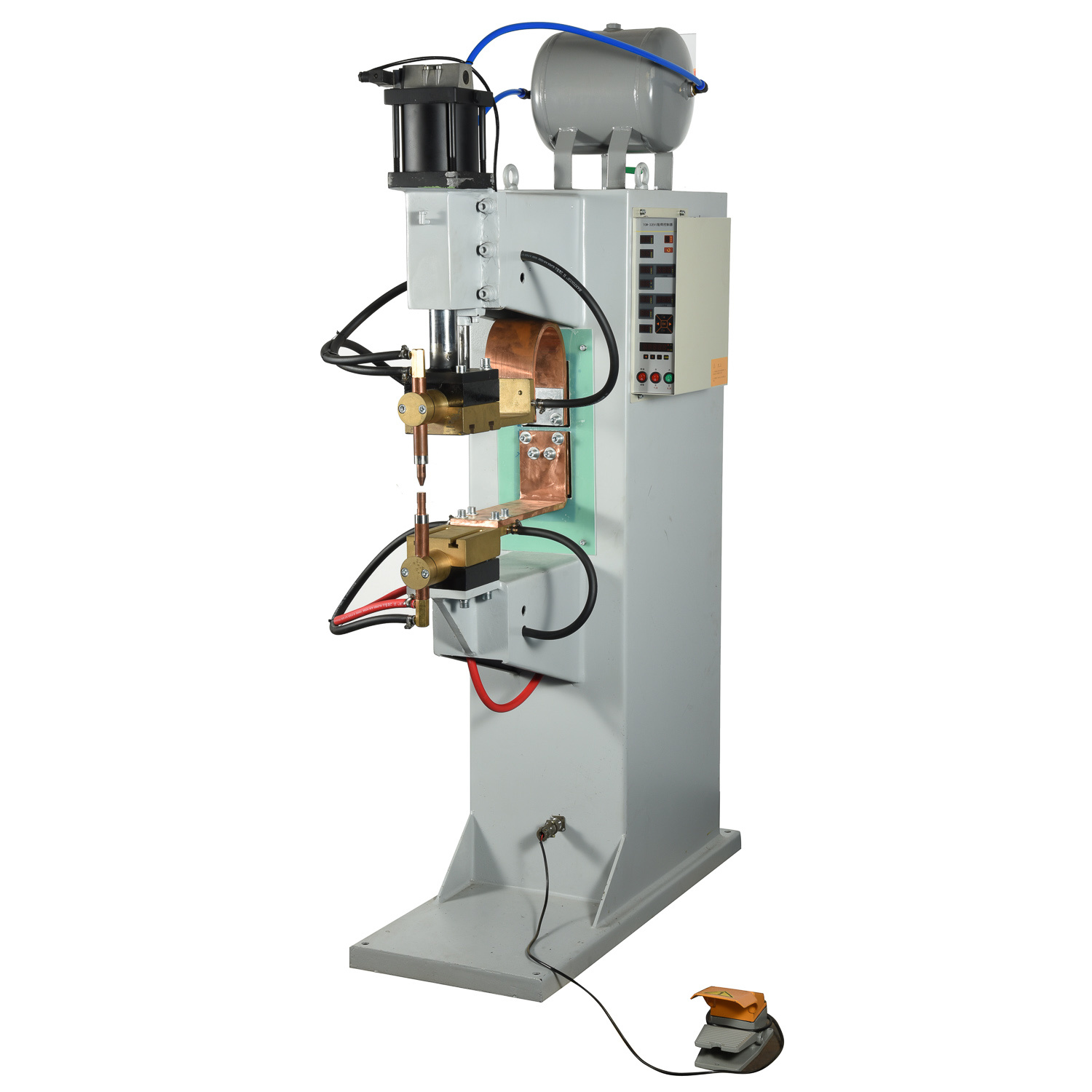

Key Components: A typical AC Spot Welder includes a transformer to convert high-voltage AC to low-voltage, high-current output, copper or copper-alloy electrodes for conductivity and pressure application, a clamping mechanism, and a control panel to adjust parameters like weld time, current intensity, and pressure. Water cooling systems are often integrated to prevent electrode overheating during prolonged use.

Types and Applications: They range from portable hand-held units for small repairs to large automated systems in production lines. Common applications include joining sheet metal in car bodies, assembling electrical components, and manufacturing metal furniture. Their ability to create quick, clean welds without filler materials makes them ideal for high-volume production.

Technical Advantages: AC spot welders offer fast cycle times (often under a second per weld), consistent results, and low operational costs. They are energy-efficient compared to other welding methods and require minimal operator training. The simplicity of their design also ensures easy maintenance and durability.

Considerations: While highly effective for thin to medium-gauge conductive metals (steel, aluminum), they are less suitable for thick materials or non-conductive alloys. Proper electrode maintenance is crucial to ensure weld quality, as worn electrodes can cause weak joints or inconsistent heating.

AC Spot Welding Machine

AC spot welding machines are foundational equipment in industrial fabrication, specializing in creating precise, high - strength welds between overlapping metal sheets. These machines operate by delivering an alternating current (AC) through electrodes, which clamp the workpieces together. The resistance at the contact point generates intense heat, melting the metal and forming a weld nugget when pressure is applied.