-

Laser welding is revolutionizing the manufacturing industry by offering precision, efficiency, and flexibility that traditional welding methods cannot match. This advanced technique uses a concentrated laser beam to fuse metals, creating strong joints with unmatched precision. It allows for the joining of materials up to 4 mm thick in a single pass, with capabilities extending to 10 mm for certain applications. Key components of a

-

Laser welding technology has revolutionized high-speed production, achieving output speeds four to five times faster than traditional TIG and MIG welding methods, while also reducing manufacturing footprint and maintenance costs thanks to its non-contact operation. This technology enables precise quality monitoring of each weld, making it ideal for industries such as automotive, aerospace, and electronics, where complex and high-quality components are essential. The versatility of laser proce

-

Laser welding machines are revolutionizing various industries by providing fast, precise, and clean joining of metal parts. This technology is essential in sectors such as automotive, aerospace, electronics, medical devices, battery manufacturing, electric motor production, pipeline construction, mold processing, eye

-

Our Laser welding machines provide precise and efficient welding solutions, delivering perfect seams with minimal energy consumption. Designed by AURO and manufactured by Huras Stanzautomation GmbH, these machines are user-friendly, requiring only a short training period for operators to get started. The low indirect

Tube Laser Machine

- manufacturer, factory, supplier from China(Total 12 Products for Tube Laser Machine)

-

Supply Ability:100 Sets/MonthOverview Features Product Parameters Detailed Photos Company Profile FAQ Overview Basic Info. Application Electronic Industry, Automotive Industry, Manufacturing Industry, Textile Machinery,Food Machinery, Aerospace Indust Technical...

-

Automatic straight seam welding machine: An automated and precise tool for straight seam welding In the subfield of metal Welding, the Automatic Straight Seam Welding Machine, with its feature of focusing on straight seam welding and fully automated...

-

Automatic straight and longitudinal seam welding machine: The automated and efficient choice for longitudinal seam welding In the field of long Straight Seam Welding of metal plates, the Automatic Straight Longitudinal Seam Welder Welding Machine,...

-

Radiator Fin Flash Butt Welding Machine: The efficient core for welding radiator finsIn the production and manufacturing of heat sinks, the welding quality of the heat sinks directly affects the heat dissipation efficiency and the service life of...

-

Condenser & Evaporator Welding Machine for HVAC Systems: Welding assurance for HVAC coreIn HVAC systems, condensers and evaporators, as the core components for heat exchange, their welding quality directly determines the system's cooling...

-

Automobile shock absorber seam welding machine: Dual guarantee of sealing and strengthIn the manufacturing of Automotive Shock absorption systems, the sealing performance of shock absorbers directly determines their service life and shock absorption...

-

Automatic Copper Tube TIG Sealing Welding Machine: An automated precision expert in copper tube sealing weldingIn fields such as refrigeration, HVAC, and bathroom fixtures, the Sealing Welding quality of Copper tubes directly affects the operational...

-

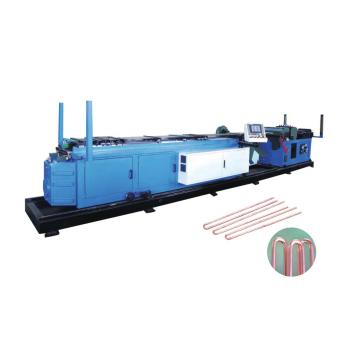

Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

-

Semi-Automatic Hairpin Bender-Precision Tube Bending Machine: A flexible choice for precise tube bendingIn the industrial chain of pipe processing and manufacturing, various types of equipment work in concert to jointly ensure the quality and...

-

CNC Vertical Hairpin Tube Expander: A model of CNC precision for hairpin tube expansion jointIn the precise chain of modern industrial production, various types of equipment, with their unique performance, jointly promote the improvement of product...

-

Vertical Hairpin Tube Expander-Manual Door Design: A convenient option for expanding hairpin tubesIn the manufacturing process of heat exchangers and other equipment, various types of equipment work in collaboration to jointly create high-quality...

-

Copper Tube Swaging Machine-Horizontal Expander with Bits: A horizontal all-rounder for copper tube processingIn the precision field of metal pipe processing, various types of equipment have built an efficient production network with professional...

Video

Related Information