Min. Order:1 Piece/Pieces

Supply Ability: 5 Sets/ Month

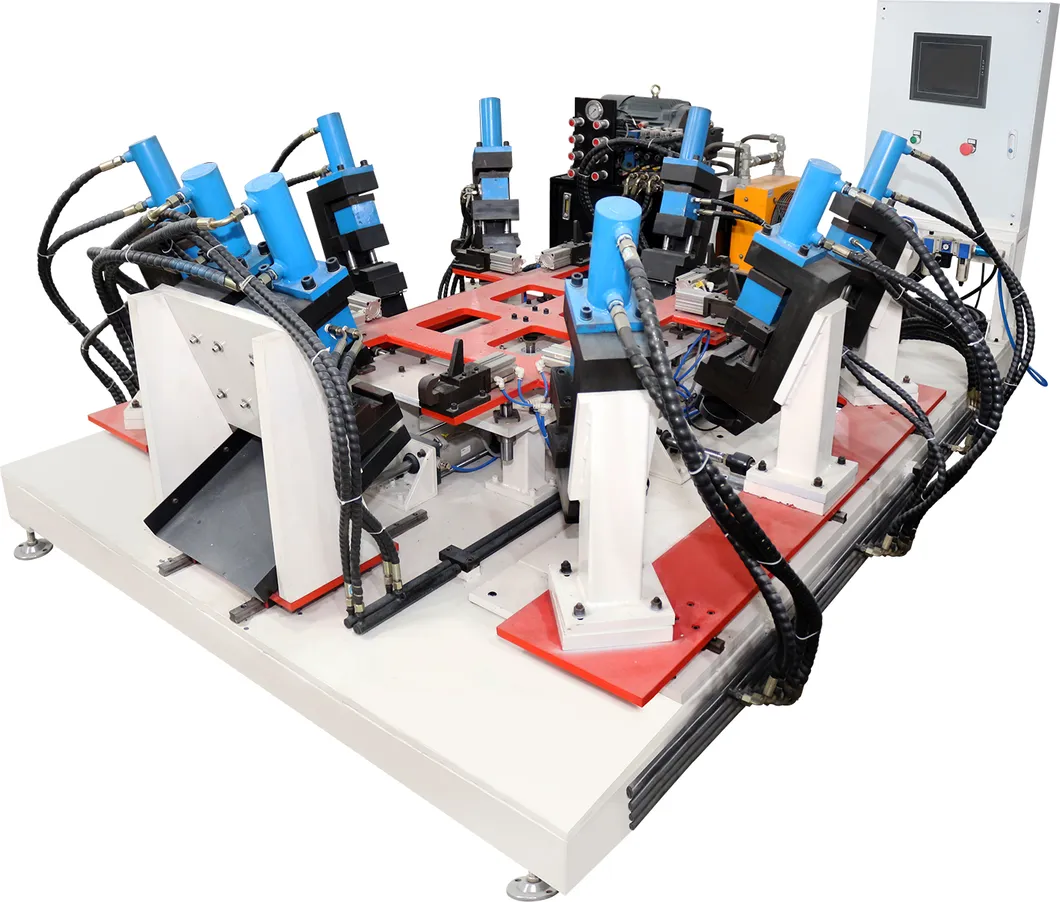

| Advantages | Save energy |

| Improve the power factor and reduce production costs; | |

| In the secondary circuit with large opening area, interference can be reduced and welding current is constant current. When the secondary winding has inductive materials (with magnetic property), it will not affect the welding | |

| make a balance of the loading of power supply device, medium frequency inversion constant current welding power source uses three-phase power and stores energy |