Style: Vertical

Welding Way: Spot Welding

Automatic Or Manual: Automatic

Transport Package: at Customer's Requrest

Specification: export standard

Trademark: xinchang

Origin: Ningbo China

Production Capacity: 5 Sets/ Month

Customization: Available

Cooling Way: Water Cooling

Control: Semi-Automatic

Supply Ability: 5 Sets/ Month

1, Ribbed square tubes and the welding of ribbed square tubes: As the products to be welded are hollow square pipe and have coating, so four welding transformers are required .

2, Welding speed requirements: No less than 40 pieces per hour, our company proposes solution according to the technical experience and customer requirements: Using the gantry welding theory, high-power, high-energy welding current.

3, Welding and material arrangement can be realized by specially designing double-feed welding molds .

The device is mainly made up of dragon gate machine body, medium frequency inversion constant current welding power source, electrical operating system, special welding pressurized cylinder, the upper and lower electrode part, double-mold frame, water cooling systems, pneumatic systems, monitoring devices, security agencies and other components and is introduced as follows:

1, machine body: The vertical strengthening structure is welded with thick steel plate in high quality and is equipped with strengthened tendon with reasonable structure and has been derived of stress.

2, MF inversion DC welding power source is mainly made up of transformer, controller, inverter, power drive, rectifier parts, capacitor plates, IGBT as well as the central control components.The feature is the original input voltage 50/60Hz cn be rectified to 1000Hz and the rectified diode of transformer secondary circuit can transform the power into constant current power source so that the secondary circuit reactance coefficients can be greatly improved (it is an important factor in causing the loss of energy before improvement), and it is almost taken into consideration in constant current welding circuit, almost, and thus production costs are minimized. Compared with conventional welding power source, it has the following advantages:

A) Save energy;

B) Improve the power factor and reduce production costs;

C) In the secondary circuit with large opening area, interference can be reduced and welding current is constant current. When the secondary winding has inductive materials (with magnetic property), it will not affect the welding;

D) make a balance of the loading of power supply device, medium frequency inversion constant current welding power source uses three-phase power and stores energy.

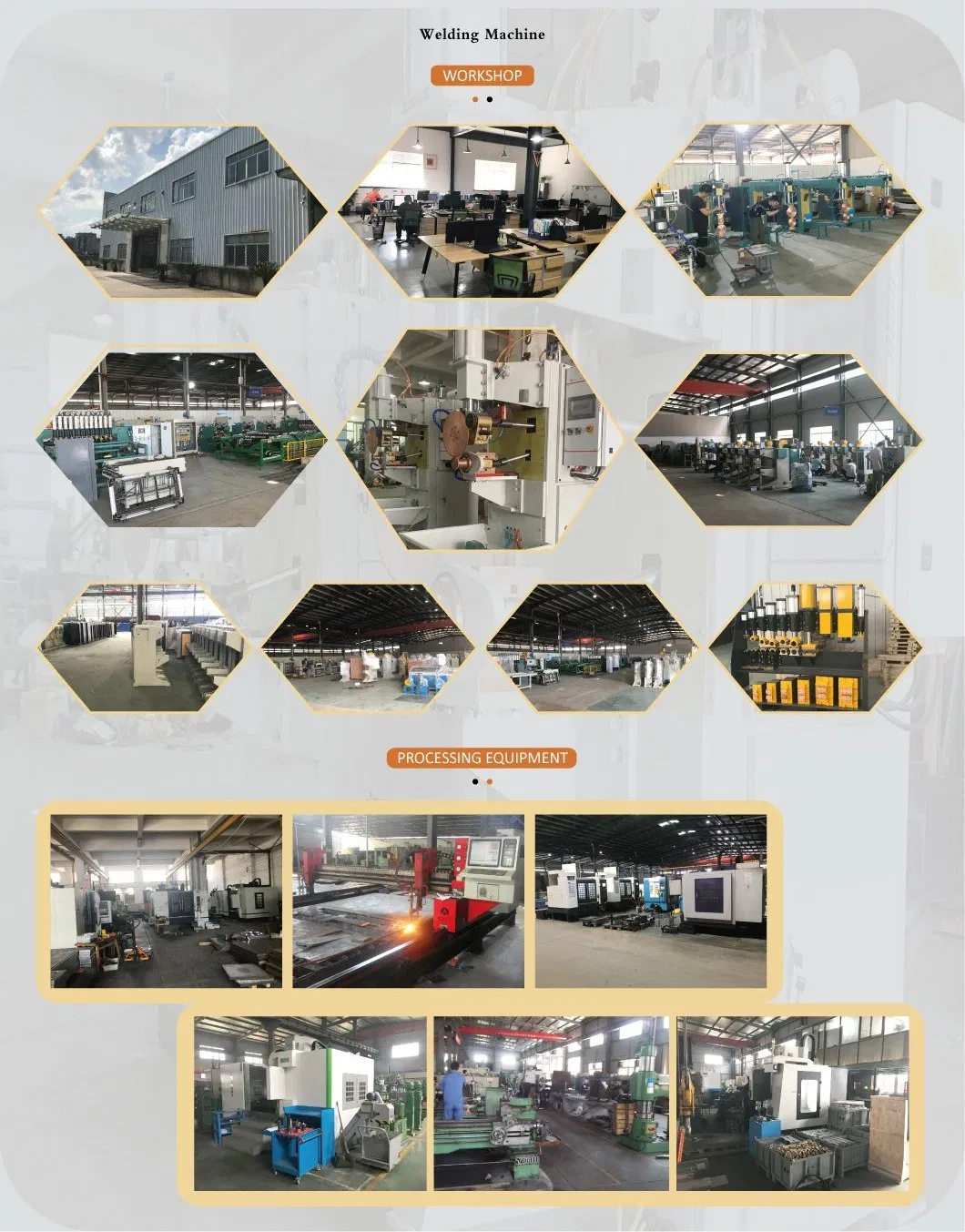

Related images

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in Friction Welding Machine, Resistance Welding Machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in Friction Welding Machine, Resistance Welding Machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.

1.Q: What about your standard delivery date ?

1.Q: What about your standard delivery date ?