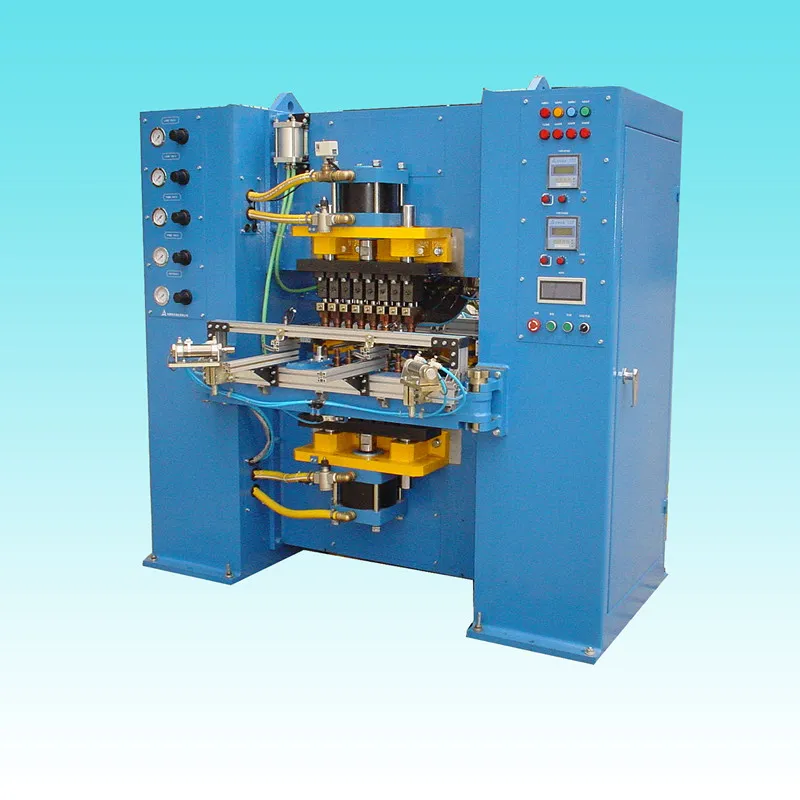

The Automatic DC Roller Welding Machine Radiator Circumferential Seam Welder is a professional automated welding equipment tailored exclusively for the circumferential seam welding of radiator elements. Integrating advanced DC roller welding technology, intelligent regulation system and humanized structural design, this machine is a core device in radiator manufacturing lines, widely applied in automotive radiators, industrial radiators, household heating radiators and other fields. It focuses on solving the pain points of unstable welding quality, high energy consumption and low efficiency in traditional radiator circumferential seam welding, providing enterprises with a reliable, efficient, energy-saving and high-quality welding solution.

With its sophisticated design and advanced technical configuration, the machine has seven core outstanding features, which comprehensively cover welding quality, operational efficiency, safety, energy conservation and equipment durability, bringing all-round upgrades to the radiator welding process:

1. Automatic speed and weld current regulation at corner radius and overlap areas: This is the core technical highlight of the machine, specially optimized for the key welding positions of radiators. The corner radius and overlap areas of radiator elements are difficult to weld, and traditional welding equipment often has defects such as uneven welds, burn-through or incomplete welding due to fixed speed and current. This machine is equipped with an intelligent sensing and regulation system, which can automatically detect the corner radius and overlap areas during welding, and dynamically adjust the welding speed and welding current in real time. It ensures that the welding parameters are perfectly matched with the welding position, making the welds at key positions uniform, firm and smooth, effectively avoiding welding defects, and greatly improving the overall welding quality and consistency of radiator elements.

2. Most reliable process safety: Safety is the top priority of industrial production, and this machine is designed with a full set of safety protection mechanisms to ensure the most reliable process safety. It is equipped with emergency stop buttons, safety door interlocks, welding current overprotection, voltage stabilization protection and other multiple safety devices, which can quickly cut off the power supply and stop the machine in case of abnormal operation, avoiding safety accidents caused by equipment failure or misoperation. At the same time, the machine’s welding process is stable and controllable, with no obvious spatter or radiation, protecting the physical health of operators and ensuring the safe and orderly operation of the production line.

3. Clean, water and oil tight weld seams: The machine adopts advanced DC roller welding technology, which realizes stable and uniform welding force and current output, making the formed weld seams clean and neat, with no burrs, no pores and no slag inclusion. More importantly, the weld seams have excellent sealing performance, reaching water and oil tight standards—this is crucial for radiators, which need to bear the circulation of cooling water or oil during operation. The tight weld seams effectively avoid leakage problems, ensure the normal operation of radiators, reduce the repair rate of finished products, and improve the reliability and service life of radiators.

4. Quick change over to different element sizes: In response to the diverse specifications of radiator elements in modern production, the machine is designed with a quick changeover structure, which can easily and quickly switch between different element sizes without complex disassembly and assembly or parameter adjustment. The quick changeover design shortens the production preparation time, reduces the downtime caused by specification replacement, and greatly improves the flexibility and adaptability of the production line. It is especially suitable for enterprises that produce multiple specifications of radiators, helping to optimize production efficiency and reduce production costs.

5. Low electric energy consumption: Adopting optimized circuit design and high-efficiency energy conversion technology, the machine achieves low electric energy consumption while ensuring welding quality and efficiency. Compared with traditional AC roller welding machines, it can save a lot of electric energy in long-term continuous operation, effectively reducing the energy cost of enterprises. The low energy consumption design not only conforms to the modern industrial concept of energy conservation and environmental protection but also helps enterprises reduce operational costs and improve market competitiveness.

6. Long electrode life of weld rolls: The weld rolls (electrodes) of the machine are made of high-quality wear-resistant, high-temperature-resistant alloy materials, which have excellent electrical conductivity and wear resistance. After special surface treatment, the electrode rolls have strong anti-oxidation and anti-adhesion performance, which can effectively reduce wear and damage during welding, extending the service life of the electrodes. The long electrode life reduces the frequency of electrode replacement, saves the cost of consumables, and reduces the downtime caused by electrode replacement, ensuring the continuity of the production line.

7. Integrated electrode roll profiling device at the machine: The machine is equipped with an integrated electrode roll profiling device, which is perfectly matched with the shape and size of radiator elements. The profiling device can ensure that the electrode rolls are closely attached to the surface of the radiator elements during welding, realizing uniform force application and stable welding. It effectively avoids the problem of uneven welds caused by the deviation of electrode rolls, further improving the welding precision and consistency of the weld seams. The integrated design also makes the structure of the machine more compact and reasonable, reducing the difficulty of maintenance and adjustment.

In addition to the Automatic DC Roller Welding Machine Radiator Circumferential Seam Welder, we also provide a complete set of radiator welding solutions, including Radiator Multispot Welding Machine and Boss Stitch Welding Machine. These three machines complement each other and cover all key welding links of radiator manufacturing—from circumferential seam welding of elements, multi-point welding of components to boss stitch welding, realizing one-stop welding of radiators. We are committed to providing high-quality, integrated welding equipment and solutions for radiator manufacturers, helping enterprises optimize production processes, improve product quality and production efficiency, and enhance core market competitiveness.