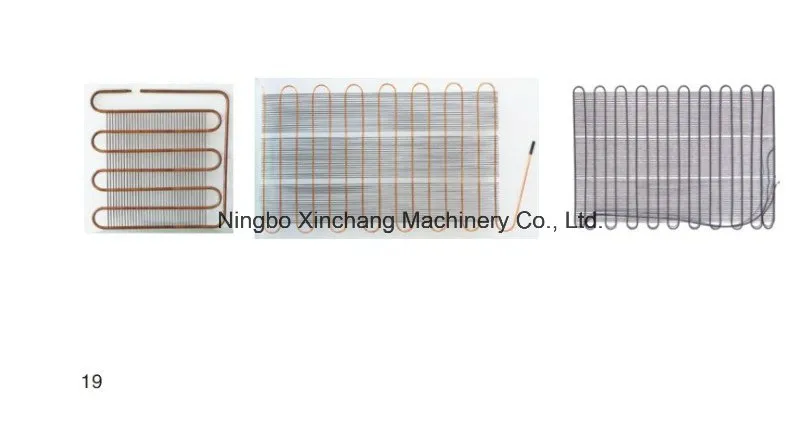

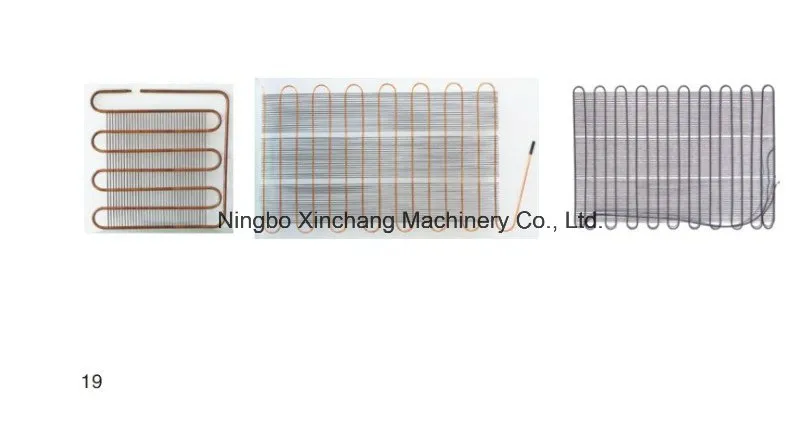

New Type Evaporator Welding Equipment Spot Weld Machine for Condenser

Features: 1, Electrode is easy to change after wear, don't need to change the complete electrode and electrode base, only for electrode parts, so decreasing the cost.

2, Machine body of thick steel sheet, not easy to deformation

3, Microcomputer control, accuracy and steady

4, Water cooling transformer: Use silicon sheets of 15000 gauss permeability to pile up. There is cooling water in inside, using full copper alloy core, reducing impedance, improving the utilization of power, 20% duty cycle to ensure the requirement of long time welding, big output power. The useful lifetime is longer, noise is smaller, structure is more compact and reasonable.

5, Fast solenoid valve, making welding speed faster, thereby the productivity is higher, therefore decreasing cost.

6, Cylinder adopt high accurate, anti-friction hard material, which is duralumin, without rust, lower friction, lower noise and loading is faster, thereby reducing the weld spatter.

7, Quality is stable, failure rate is low, therefore machine life is longer

Application: Suitable for condenser and evaporator. | | DNW3-250-1200 | DNW-150-3 | DNW2-150-4 |

| Rated capacity (KVA) | 250 | 150 | 150 |

| Transformer | 1200type 250KVA

MF inverter transformer | 150KVA AC

transformer | 150KVA AC

transformer |

| Rated voltage (V)/ Phase | 380/3 | 380/1 | 380/1 |

| Rated frequency(HZ) | 50 | 50 | 50 |

Max. short circuit

Current (KA) | 42.9 | 36 | 36 |

| Duty cycle(%) | 50 | 20 | 20 |

| Max. pressure(N) | 5315 | 5315 | 5315 |

Upper electrode

Stroke (mm) | 60 | 60 | 60 |

Lower electrode

Stroke (mm) | 40 | 40 | 40 |

Cooling water flow

(L/min) | 24 | 6 | 6 |

Max. welding width

each electrode

(mm) | 155mm | 100 | 100 |

Welding speed

(pcs/ 8h) | 5500 | 1000 | 1000 |

Overall dimension

(mm) L*W*H | 2600*670*1685 | 460*1100*1900 | 1250*680*1840 |

| Air pressure | ≥ 0.6mpa | ≥ 0.6mpa | ≥ 0.6mpa |

| Insulation class | F | F | F |