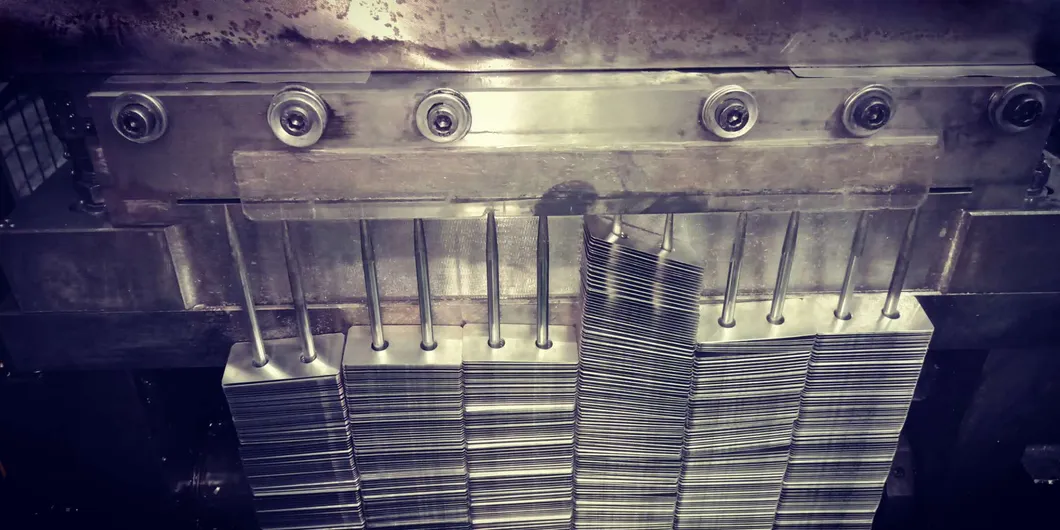

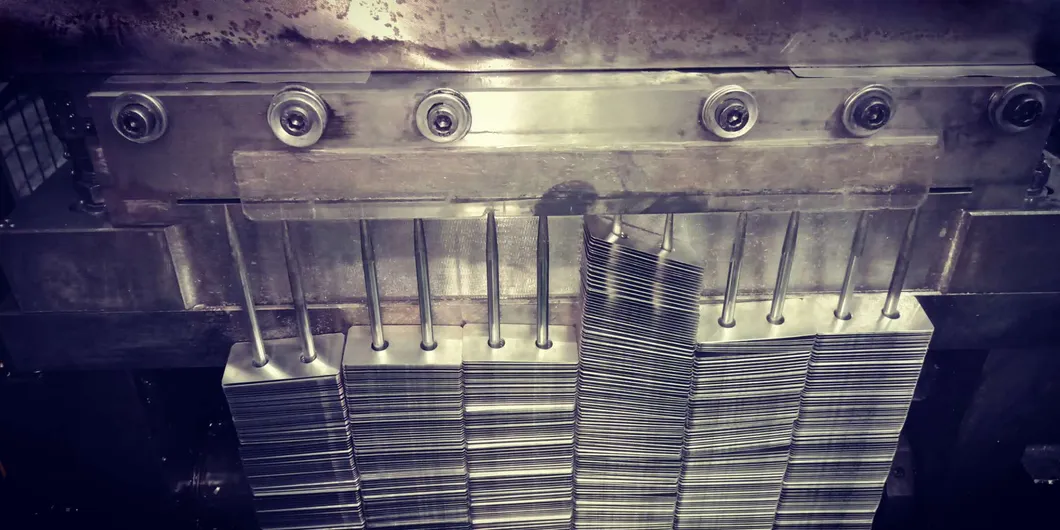

High Speed Automatic Mini Type Fin Punching Machine

This high-speed punch press is a specialized piece of equipment customized for processing refrigerator evaporator fins. It utilizes an FX2N series PLC as its core control system, enabling centralized and precise control of the entire processing flow. Combined with variable frequency speed control technology, the punching speed can be flexibly adjusted according to production needs, balancing adaptability to different fin specifications with ease of operation.

The equipment operates in a continuous cycle mode. Through a pre-programmed PLC, it precisely controls the coordinated operation of each stage, including punching, feeding, and positioning. The seamless transitions between processes effectively reduce non-production time losses and significantly increase output per unit time. Its compact and rational overall structural design ensures equipment stability while significantly saving workshop installation space, facilitating production line layout planning and subsequent maintenance.

In terms of operation, the equipment adheres to a simple and user-friendly design philosophy, equipped with a user-friendly interface. After simple training, operators can quickly master parameter settings, start/stop control, and daily inspections, reducing the barrier to manual operation and the error rate. The transmission system employs high-precision components and optimized design, ensuring smooth and reliable operation. It effectively reduces equipment vibration and noise while guaranteeing positioning accuracy during the stamping process, preventing transmission deviations from affecting fin processing quality.

With its highly efficient continuous operation capability, stable transmission performance, and precise control system, this equipment not only boasts extremely high production efficiency but also effectively ensures consistent product quality. The dimensional accuracy and forming effect of the processed refrigerator evaporator fins strictly adhere to design standards, providing a solid guarantee for the heat exchange efficiency and operational stability of the refrigerator evaporator. It is widely applicable to large-scale, standardized production scenarios in the refrigerator manufacturing industry.

| For raw materials | Aluminum foil volume, 286-316 - mm wide, 0.16 0.2 mm thick |

| Piece rate | 180-300 times/min |

| Output quantity | 5 / time (depending on piece mold |

| Take out the way | Vertical and horizon, back, back |

| Capacitance | About 5 KVA (380 v, 50 hz) |

| Main equipment | high-speed punch ontology, die. |

| Auxiliary equipment | uncoiling machine |