Min. Order:1 Piece/Pieces

Warranty: 1-year

Condition: New

Certification: ISO 9001:2008, CE

Automation: Automatic

Suitable For: Aluminum

Type: Cnc Bending Machine

Hydraulic Pump Pressure: 3-6MPa

Name: Bending Machine

Bending Mode: by Servo Motor

Stroke Setting Model: by Servo Motors

Transport Package: Wooden Case

Specification: According to the Machine Model

Trademark: xinchang

Origin: Ningbo China

Production Capacity: 20 Sets/ Month

Customization: Available

After-sales Service: Life Long

Waterproof Rating: IPX-8

Supply Ability: 20 Sets/ Month

1, Composition and Structure

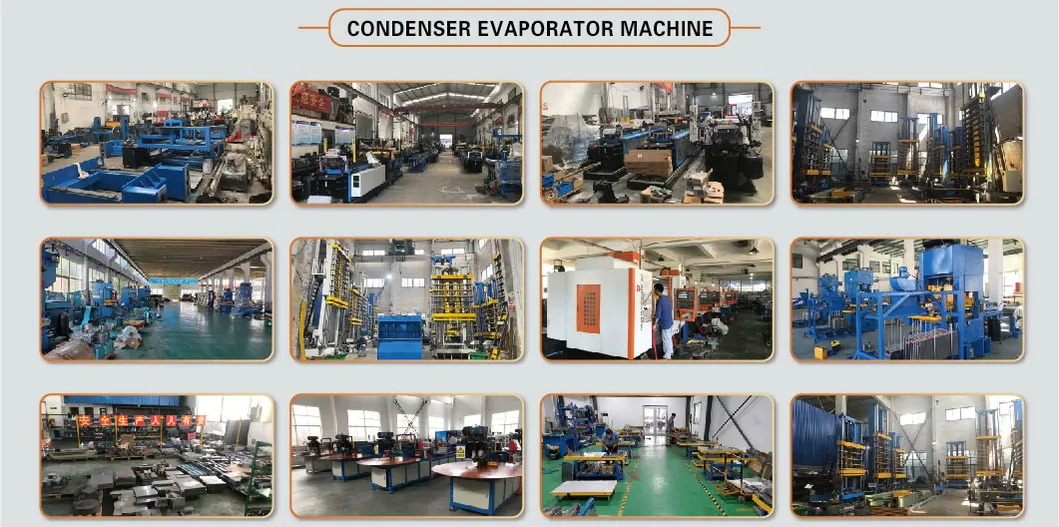

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in Friction Welding Machine, Resistance Welding Machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.