Hydraulic Exhaust Mandrel Twisted Tool Pipe Diagonal Making Machine

Product Composition and Structure

The equipment is composed of workstation, flattening die, positive pressure cylinder, lateral pressure cylinder, hydraulic station and electric control device. The whole set of action is driven by oil cylinder, while the electric appliance is controlled by relay.

I. The workstation is the square tube and welded-steel plate construction, and equipped with hydraulic station.

II. The flattening die is divided into 3 parts through wire-electrode cutting, and guide pillars are installed at two sides. The external part is fixed with the countertop, and the rest two are movable parts, with spring between them. The poling guide plate made by Bakelite plate is installed on the flattening module.

III. The low-voltage apparatus of electric control gear adopts the famous imported brand.

Equipment Operating Instructions

Plug the folding pipes into the flattening module through pipes, tread the foot pedal, make the positive pressure cylinder and lateral pressure cylinder move together, and they will return automatically after they are pressed in place. At last, take the pipes out.

Equipment Maintenance

Operators can only operate the equipment after they get familiar with the equipment structure, performance and its essential points of operation. Feature

| The working pressure of hydraulic pump is generally adjusted to be 3-6Mpa. |

| It needs to add the lubricating oil once per shift between the friction surfaces of guide pillar and movable blocks. |

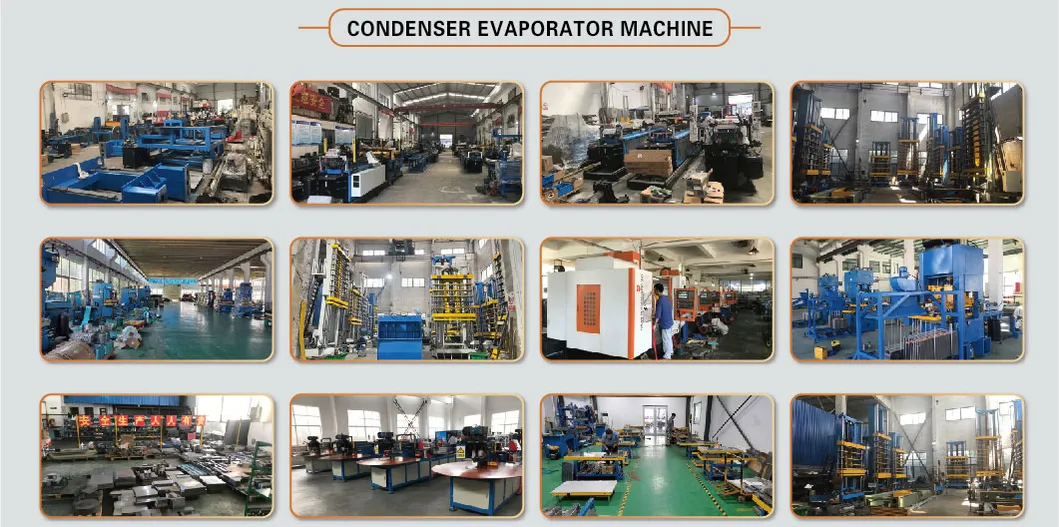

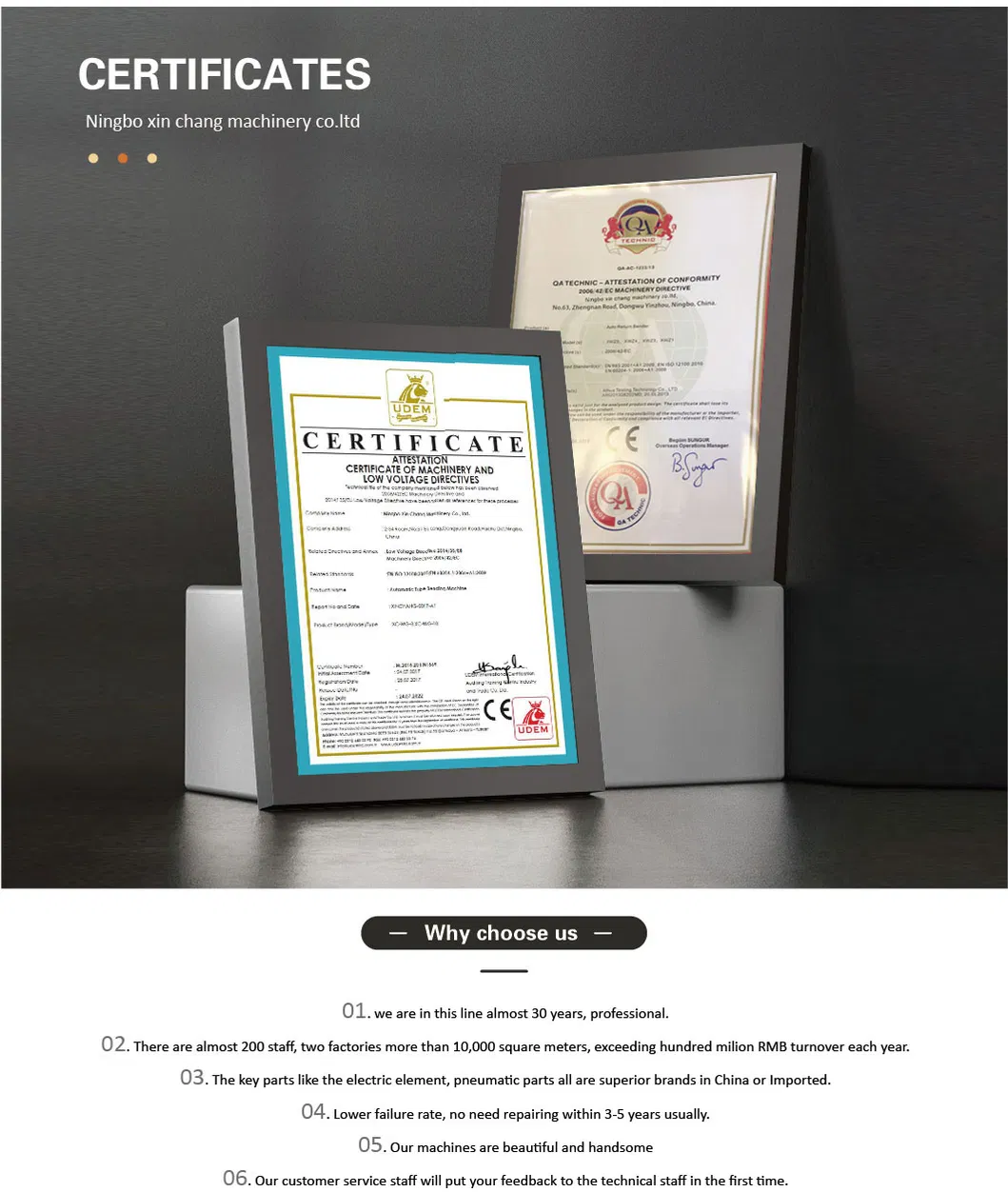

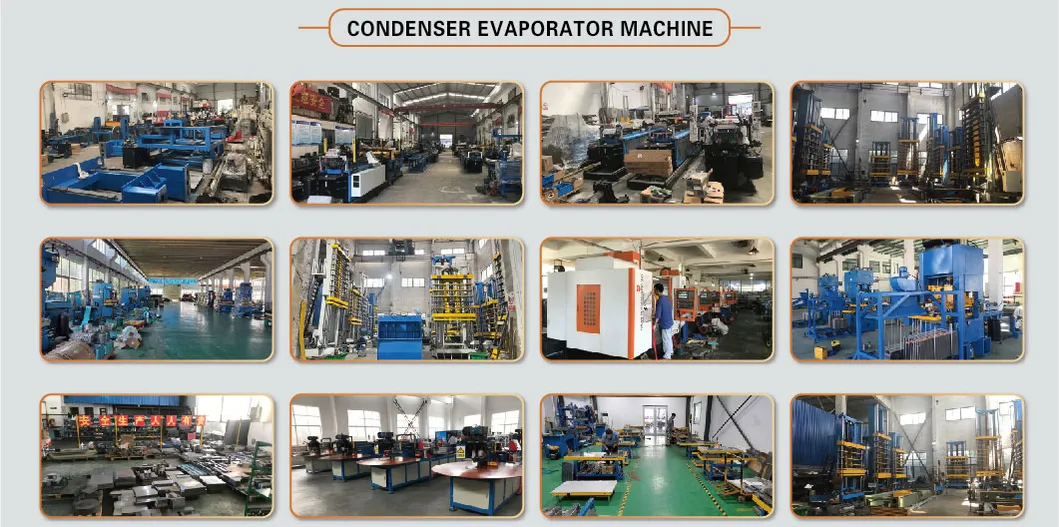

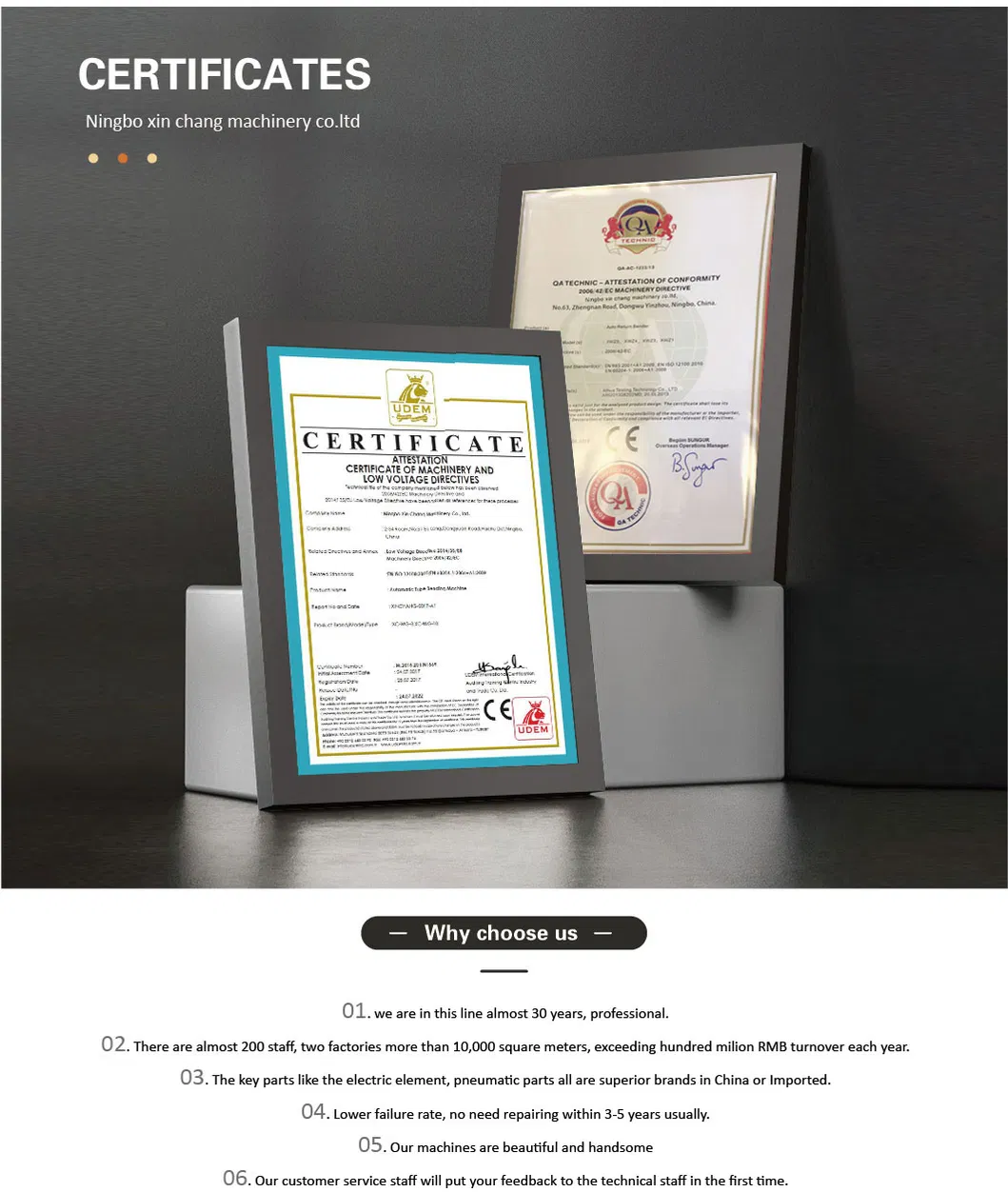

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in Friction Welding Machine, Resistance Welding Machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.

Over the years, we have exported so many machines to 30 and more countries, such as France,Spain,Poland,Russia,Indonesia,Vietnam,Pakistan,India,Mexico,Egypt etc.

Our main products are Heat exchanger equipment, Friction welding machine, Spot Welding Machine, Projection Welding Machine, Butt Welding Machine, Seam Welding Machine, Multi Head Welding Machine For Wire Mesh, and other various special welding machine for metal connection in different industries.

We always adhere to the management idea of "Integrity, profession, innovation, and win-win", to make Xin Chang becomes trustworthy enterprise of customers. Good product quality, perfect after-sales service, and professional technical support make customers choose no regrets and worry-free use.