-

Common myths surrounding welding in manufacturing can significantly hinder productivity and efficiency. Many believe that welders spend 50% to 60% of their time actively welding; however, the reality is that arc-on time averages only 12% to 15%. This discrepancy is largely due to non-value-added activities such as grinding spatter and machine setup. By optimizing machine parameters, manufacturers can drastically reduce spatter. Additionally, misconceptions about pulsed MIG being slower than t

-

95% of failed welds stem from inconsistent pressure, highlighting the importance of maintaining precise control in the welding process. Inconsistent pressure can lead to weak joints and costly rework, ultimately affecting project timelines and budgets. Our advanced welding machine addresses this issue head-on by ensuring a remarkable precision of ±5 bar. This level of accuracy significantly reduces the risk of weld failures, providing you with the confidence that each weld is performed to th

-

The investigation delved into the sensitivity of friction stir welding (FSW) to common fit-up variations, such as weld-path misalignment, permissible plate gaps, void sizes in the weld path, and variations in tensile properties along the weld. The study revealed that FSW is capable of producing sound, defect-free joints in 0.125-inch thick 7075-T73 plates, even in the presence of typical fit-up discontinuities. It was established that the tolerance for weld path misalignment is closely associ

-

Flash butt welding errors are frequently linked to inferior equipment, with an alarming 68% of mistakes stemming from the use of inexpensive tools. To steer clear of such pitfalls and guarantee top-notch welding outcomes, it is essential to invest in reliable and efficient equipment. Never compromise on quality; selecting the right tools is vital for achieving optimal performance and reducing errors in your welding operations.

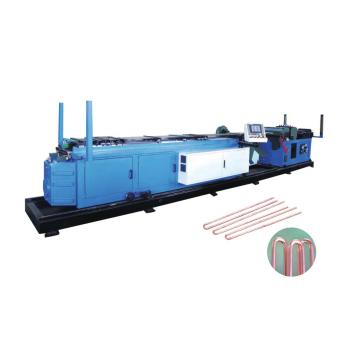

Condenser Coil Bending Machine

- manufacturer, factory, supplier from China(Total 12 Products for Condenser Coil Bending Machine)

-

Coil Bending Machine: a precision master for forming Condenser coilsIn the core process of condenser manufacturing, each step of the forming process directly affects the heat dissipation efficiency and operational stability of the equipment. The...

-

Supply Ability:100 Set/ YearProfessional Coil Bender for Condenser Coils Heat Exchanger Product Description I. Equipment Application This equipment is specifically designed for processing air conditioner condensers. Its core function is to precisely bend air conditioner...

-

Supply Ability:100 Set/ YearOverview Product Description Detailed Photos Company Profile FAQ

-

Supply Ability:500 Set / MonthOverview Product Description Detailed Photos Company Profile FAQ Overview Basic Info. Material Carbon Tool Steel Processing Method Punching and Shearing Mould Technics Cutting Die Process Combination Si

-

Supply Ability:50sets/ Month Aluminum Tube BendingOverview Product Description Detailed Photos Company Profile FAQ

-

Supply Ability:100 Set/ YearOverview Basic Info. Power Source: Hydraulic Pressure Feature: High Efficiency Certification: CCC, ISO9001, CE Warranty: 12 Months Customized: Customized Advantage: Work Flexible Condition: New Name: Vertical Tube Expander OEM: Accept Workpiece...

-

Supply Ability:50sets/ Month Aluminum Tube BendingCNC Automatic Condenser Pipe Bending Machine Product Description A. Scope of applicationa> Diameter of tube, if the dia is φ4-φ8mm, the thickness is 0.5-1mm, if dia is more than φ8-12mm, the thickness is 0.71-1mm (other size can be achieved by...

-

Supply Ability:100 Set/ YearOverview Product Description Detailed Photos Company Profile FAQ

-

Heat Exchanger Hairpin Bender-Precision Coil Bending Machine: The core tool for precision forming of heat exchangersIn the precise system of heat exchanger manufacturing, every piece of equipment plays an indispensable role. The Friction Welding...

-

Supply Ability:100 Set/ YearOverview Product Description Detailed Photos Company Profile FAQ

-

CNC Condenser Pipe Reducing Machine: the precision fitting expert for Condenser pipesIn the manufacturing system of condensers, the dimensional compatibility of pipes directly affects the heat exchange efficiency and system sealing performance. The...

-

Supply Ability:20set / MonthsAutomatic Accumulator Condenser Welding Machine for Aluminum Coils Product Description The automatic accumulator condenser welding machine is a specialized piece of equipment engineered for precision welding of accumulators to evaporators or...

Video

Related Information