1. Usage

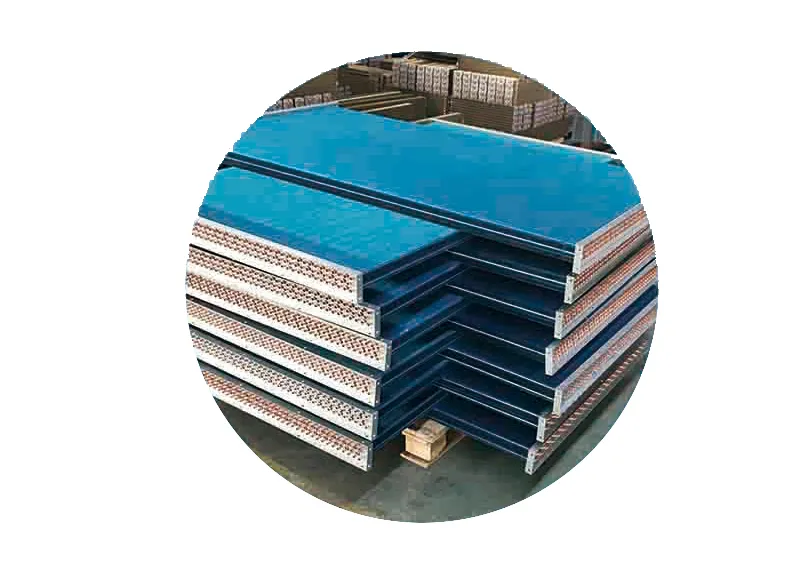

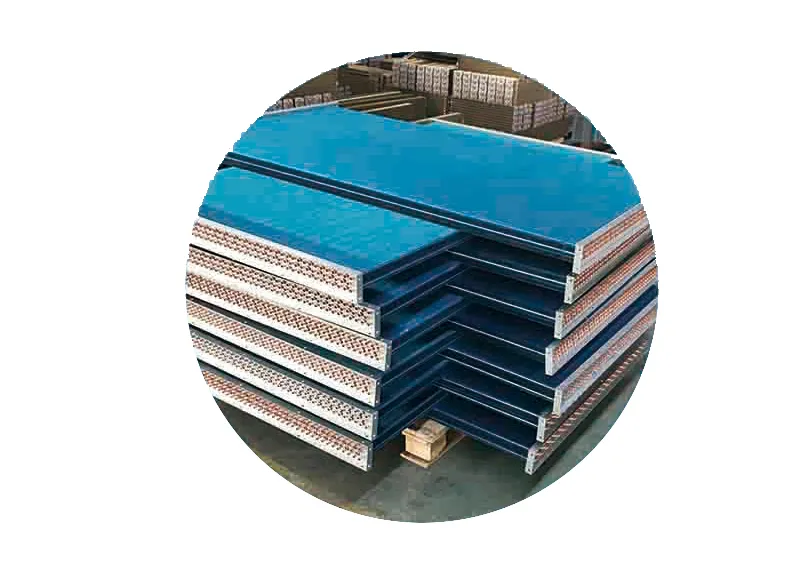

This specialized expander is tailor-made for the processing of fin heat exchangers, serving as a core piece of equipment in the heat exchanger manufacturing process. Its key advantage lies in the integration of multiple critical processes into a single working cycle: specifically, the pipe expanding, flaring, and flanging processes required for fin heat exchanger assembly are completed consecutively without the need for manual transfer of workpieces between different machines.

This integrated design not only greatly reduces the number of intermediate operation links, shortens the overall processing cycle, and improves production efficiency, but also avoids dimensional deviations caused by repeated clamping and positioning of workpieces. By ensuring the consistency and precision of each process, it effectively enhances the assembly quality of fin heat exchangers—promoting tight bonding between copper tubes and fins, optimizing heat transfer performance, and ensuring the stable operation of the final heat exchange equipment. Whether for small-batch trial production or large-scale mass production, this expander can meet the efficient and high-precision processing requirements of fin heat exchangers.

2. Specifications

- Workpiece length range: The machine supports processing of workpieces with standard lengths of 600mm, 800mm, 1000mm, and 1200mm. These specifications cover the mainstream size range of fin heat exchangers in industries such as refrigeration, air conditioning, and industrial heat exchange, ensuring strong versatility and adaptability to different application scenarios.

- Special configuration for small-length workpieces: For workpieces with lengths of 600mm or 800mm (common in small and medium-sized fin heat exchangers), the machine offers two structural options: internal oil cylinder type and external oil cylinder type. The internal oil cylinder type features a compact structure, which is suitable for occasions with limited installation space and requires precise control of the expansion force; the external oil cylinder type facilitates maintenance and debugging, and has stronger load-bearing capacity, making it ideal for long-term continuous processing of small-length workpieces. Users can choose the appropriate type according to their actual production conditions and processing requirements.

- Customization service: In addition to the standard specifications, we provide personalized customization services for the expander. Considering that different users may have special requirements for fin heat exchangers (such as non-standard workpiece lengths, special expansion force requirements, or matching with specific production lines), our professional technical team can tailor the machine's structure, power configuration, control system, and processing parameters according to the user's detailed needs, ensuring that the equipment perfectly fits the user's production process and realizes efficient and precise processing of special-type fin heat exchangers.

*Workpiece length: 1600mm , 2000mm , 2500mm , 3000mm etc , the length different , the machine specification will be different

*For the length of workpiece less than 1600mm , machine is with manual door or double rotary worktable

*For the length of workpiece more than 1600mm , machine is with turnover door oblique 84° also with the manual door which is for the workpiece length less than 1200mm

*For the length above 1600mm , the machine design is interal oil cylinder type.

We could customize the machine at your needs.