Automatic Heat Exchanger Portable Pipe Expander Bending Machine for Coils

I. Equipment Application

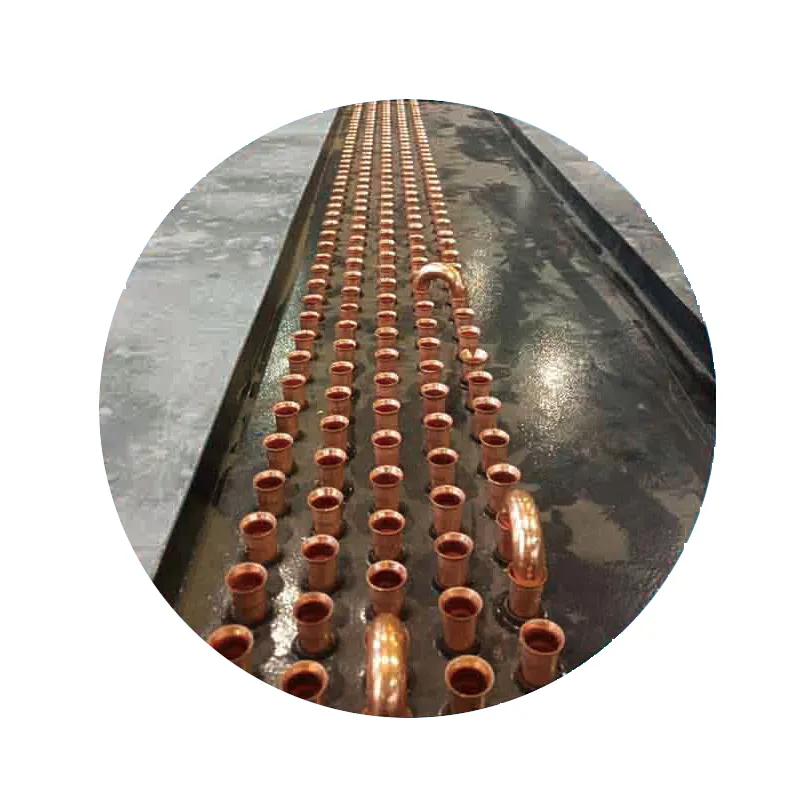

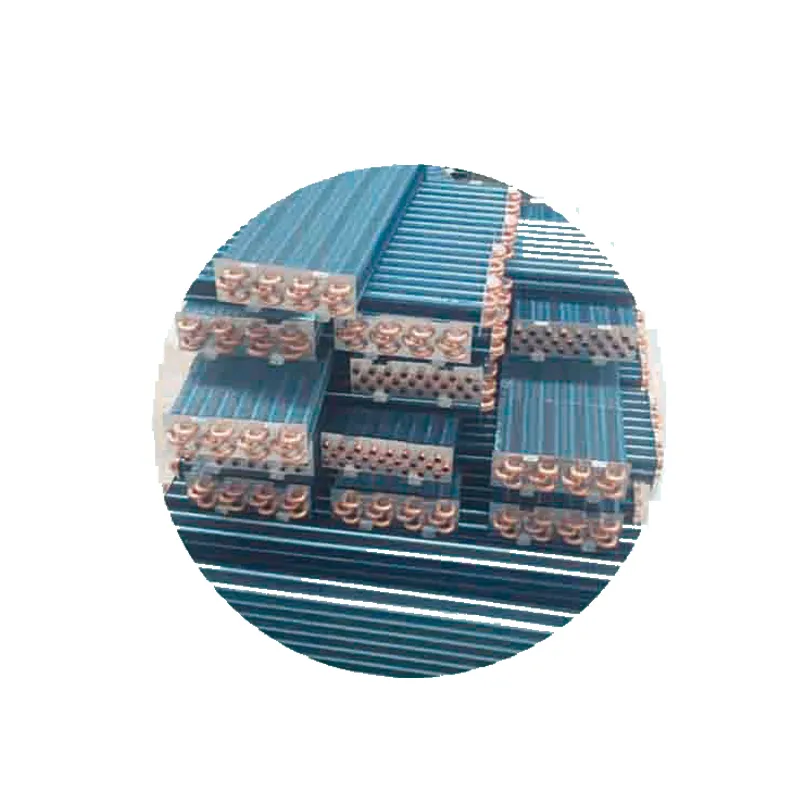

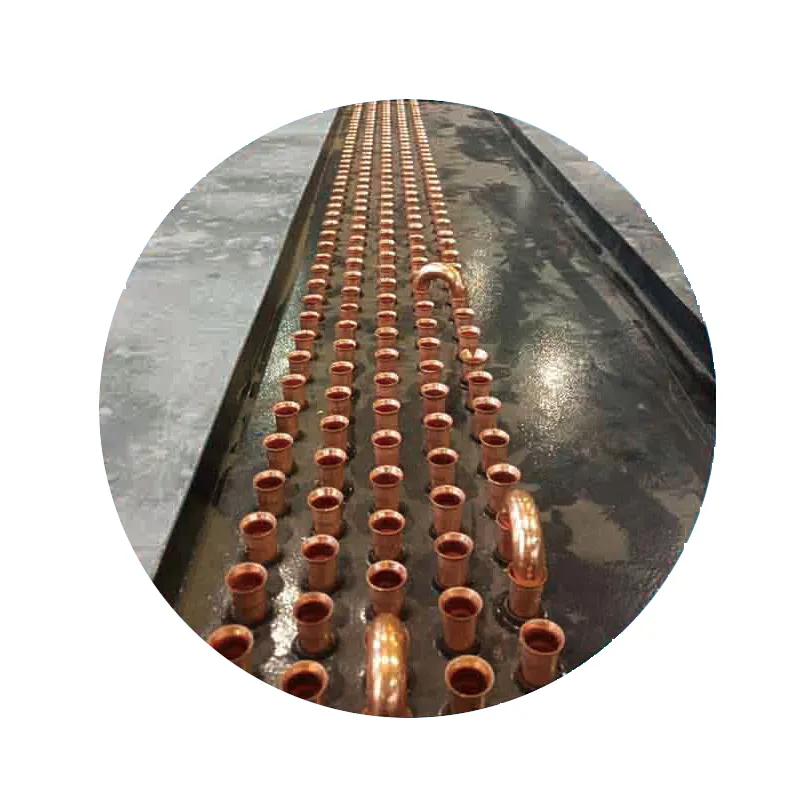

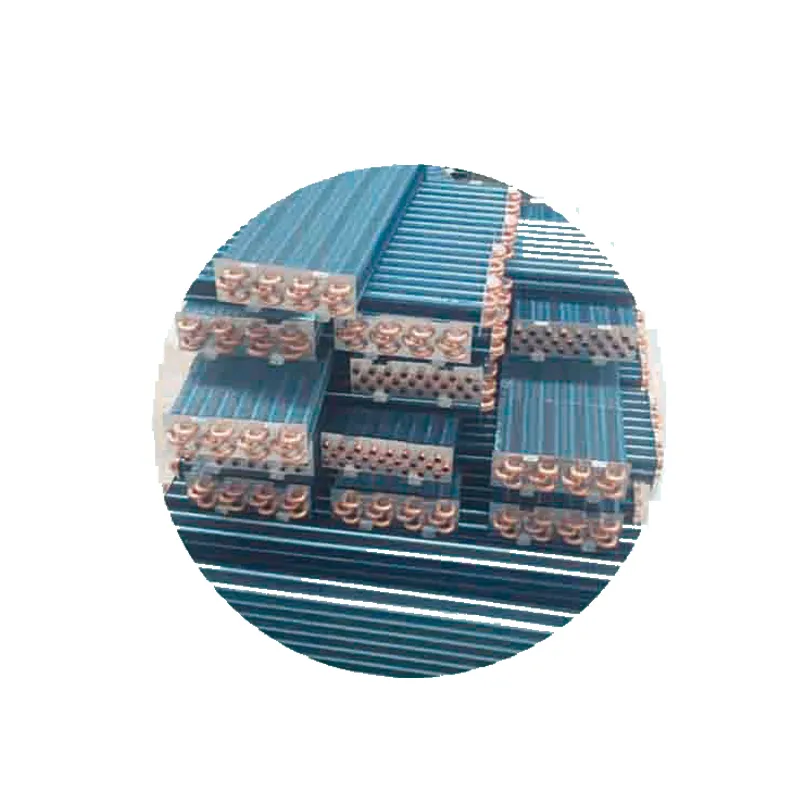

This equipment is specifically designed for the tube expansion process of heat exchanger coils and is a core piece of specialized equipment in the heat exchanger production process. Its core function is to achieve diameter expansion at the ends or in specific sections of the copper tubes in the heat exchanger coils through precise tube expansion technology, ensuring a tight assembly of the coil with the tube sheet, end caps, and other components, thereby improving the sealing performance and heat exchange efficiency of the heat exchanger. This equipment is widely applicable to the coil processing scenarios of various heat exchanger products, including air conditioning heat exchangers, industrial chiller heat exchangers, and HVAC heat exchangers, providing key process guarantees for the stable operation and efficient heat exchange of heat exchangers.

II. Core Technical Parameters

- Compatible Copper Tube Diameter: Φ7-Φ25mm. This parameter covers the commonly used copper tube specifications for mainstream heat exchanger coils. Whether it's the small-diameter copper tubes for small household air conditioning heat exchangers or the large-diameter copper tubes for large industrial heat exchangers, precise adaptation can be achieved without frequent changes to core tooling, effectively improving the equipment's versatility and production flexibility.

- Expansion Length: Customizable according to the buyer's actual production needs. The equipment, through its adjustable mechanical structure and intelligent control system, can precisely control the tube expansion length, enabling expansion from short-distance end tubes to long-section segmented tubes. It fully matches the personalized processing requirements of different models and structures of heat exchanger coils, ensuring the adaptability and precision of the processing technology.

- Expansion Speed: 5-11 meters/minute. The equipment adopts a high-efficiency power transmission system and optimized expansion mechanism design, achieving high-speed and stable expansion operations. This speed range can be steplessly adjusted according to the specifications, material, and expansion precision requirements of the copper tubes being processed. While ensuring expansion quality (such as avoiding copper tube deformation and cracking), it maximizes production efficiency and meets the production needs of different capacity scales.

III. Equipment Model Design

To adapt to the capacity needs and production layouts of different users, three models are available: single-tube, double-tube, and four-tube. Users can flexibly choose according to their production scale, coil batch size, and workshop space conditions:

- Single-tube model: Adopts a single-station, single-channel design, with a compact structure, small footprint, and simple and easy-to-understand operation.

- Dual-tube model: Utilizing a dual-station parallel design, this model can simultaneously expand two copper tubes. Compared to the single-tube model, it nearly doubles the production capacity while balancing space requirements and efficiency. Suitable for medium-batch heat exchanger coil manufacturers, it is the preferred model for balancing capacity and site costs.

- Four-tube model: Featuring a four-station synchronous operation design and equipped with a highly efficient automated feeding and positioning system, this model enables simultaneous and precise expansion of four tubes. Its significant capacity advantage meets the needs of large-scale, standardized heat exchanger coil batch production, effectively reducing unit product processing costs and enhancing the company's market competitiveness.

| Pipe No. bending at one time | 1-8 pcs |

| Hairpin pipe length | Min 200-Max 1250 / 1650 / 2150 / 2650 / 3150 / 5000 |

| Bending mode | by servo motors |

| Positioning & unloading mode | by servo motors |

| Stroke setting model | by servo motors |

| Available copper pipe diameter | ∮ 5 - ∮ 16 |

| Bending center | 16-60mm |

| Efficiency (one cycle) | when L≤1,000, t <12sec |

| Length precision | ±0.8mm |

| Flattening rate in thickness of bending part | ≤15% |