Equipment For Heat Exchanger

Fin Die

Fin Press

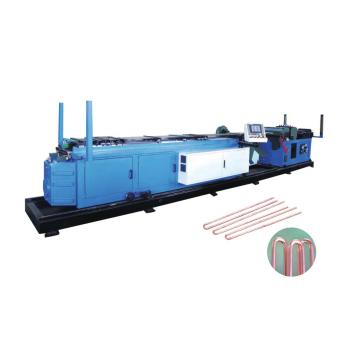

Fully Automatic Hairpin Bender

Semi-automatic Hairpin Bender

Vertical Expander

Horizontal Expander

Automatic Return Bender

Automatic Ring Inserting Machine

Automatic Welding Machine

Cleaning Machine For Return Bend

Coil Bender

Mobile Expander

Potable Expander

Equipment For Staggered Type Evaporator

Equipment For In-line Type Evaporator

Pipe Straightening & Cutting Machine

Automatic TIG Welder For Accumulators

3D Pipe Bending Machine

Automatic Copper Pipe Drawing Machine

Automatic Decoiling,bending And Pipe End Processing Integrated Machine

CNC Hole Punching And Flanging Machine

CNC Hole Punching And 3D Bending Machine

CNC Spinning Machine

Pipe End Processing Machine

Pipe Flaring Machine

Pipe Reducing Machine

Other Equipment for Heat exchanger

Core Heat Transfer Components

Tubes (Shell-and-Tube Exchangers): Thin-walled metal tubes (often copper, stainless steel, or titanium) form the primary surface for heat transfer. Fluids flow inside tubes (tube side) and around them (shell side); designs like U-tubes or straight tubes suit different pressure/temperature needs.

Plates (Plate-and-Frame Exchangers): Corrugated metal plates (stainless steel, titanium) with gaskets create alternating channels for hot/cold fluids. Their large surface area and turbulent flow boost efficiency, ideal for low-to-medium pressure applications.

Fins: Extended surfaces (aluminum, copper) attached to tubes/plates enhance heat transfer by increasing surface area. Used in air-cooled exchangers (e.g., car radiators) where air (low heat capacity) is the heat sink.

Structural & Sealing Equipment

Shell & Tube Sheets: The shell (a cylindrical metal casing) encloses tubes; tube sheets (thick metal plates) secure tube ends, separating tube-side and shell-side fluids.

Gaskets & Seals: Elastic gaskets (EPDM, nitrile, PTFE) prevent cross-contamination in plate-and-frame or shell-and-tube exchangers. They resist high temperatures/chemicals to maintain system integrity.

Frames: Rigid metal frames (steel) hold plates in place in plate-and-frame exchangers, enabling easy disassembly for cleaning.

Auxiliary & Control Equipment

Pumps & Fans: Pumps circulate liquid fluids (e.g., water, oil) through the exchanger; fans drive air in air-cooled models, ensuring consistent fluid flow for steady heat transfer.

Temperature/Pressure Sensors: Thermocouples or RTDs monitor fluid temperatures, while pressure gauges detect blockages or leaks. These feed data to control systems for adjustments.

Valves: Control valves regulate fluid flow rates; check valves prevent backflow. Relief valves protect against overpressure, a critical safety feature for high-temperature processes.

Cleaning Tools: Brushes, high-pressure water jets, or chemical cleaning systems maintain component cleanliness—fouling (scale, debris buildup) reduces heat transfer efficiency over time.

Material Selection Criteria

Equipment materials depend on fluid properties (corrosiveness, viscosity), temperature, and pressure. For example, titanium resists seawater corrosion (used in marine exchangers), while carbon steel suits non-corrosive industrial fluids. Gasket materials are chosen for chemical compatibility (e.g., PTFE for acidic fluids).

Proper selection and maintenance of this equipment ensure heat exchangers operate efficiently, reliably, and safely, minimizing energy waste and extending service life across industries.